Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Brand: MCWAY

Status: New

Warranty Period: 6 Months

Applicable Industry: Hotels, Food &Amp; Beverage Factory, Machinery Repair Shops, Manufacturing Plant, Other, Energy &Amp; Mining

Out-of-warranty Service: Online Support, Spare Parts, Video Technical Support

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Hot Product 2019

Place Of Origin: China

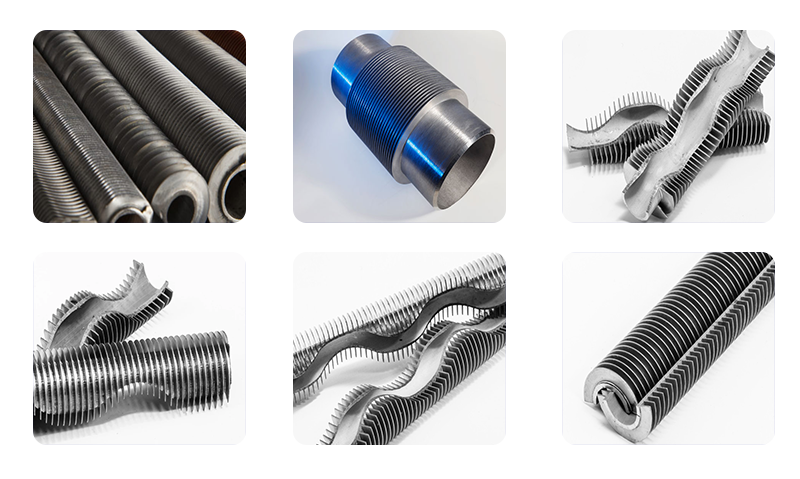

Types Of Parts: Finned Tube

Packaging: Wooden box packaging

Transportation: Ocean,Land,Air,Express,Others

Place of Origin: CHINA

Supply Ability: 50000meter/month

Port: Shang Hai,Ning Bo

Payment Type: Paypal,T/T

Incoterm: EXW,CIF,CFR,FOB,FCA,CIP

How to choose a Finned Tube Heat Exchanger is indeed a problem that consumers need to think about. Some focus on thermal efficiency and whether they can achieve obvious results in a short period of time; some focus on corrosion resistance due to environmental factors; they also care about whether the appearance is beautiful

1. The working pressure of the Finned Tube Heat Exchanger should be compatible with the working pressure of the system and comply with the relevant current product standards;Large Finned Tubes

2. Civil buildings should adopt beautiful and easy-to-clean products;

3. For industrial buildings with a large amount of dust or high requirements for dust prevention, easy-to-clean products should be used;

4. Corrosion-resistant products should be used in industrial plants with corrosive gases or in rooms with high relative humidity;

5. When steel is used, a closed system should be used to meet the product's water quality requirements. The heating system should be filled with water for maintenance in non-heating seasons;Large Finned Tubes

6. When using aluminum products, internal anti-corrosion aluminum products should be selected to meet the product's water quality requirements;

Extruded fins are manufactured by compressing an aluminum billet or sleeve onto a parent tube. The billets are exposed to extremely high pressures which actually cause the fins to "grow" into the Final fin profile. This process results in a very strong joint with excellent heat transfer capabilities. Production Process For composite Finned Tubes, line-compression or rolling-stripping-cleaning-pressure testing-blowing-packing is needed. The finned tube is made of iron-aluminum or copper-aluminum tube composite fins. It has dense feathers, low heat resistance, good heat transfer performance, high strength, low loss, Strong Corrosion Resistance, and is not easily deformed. Long lifespan in hot and cold conditions. The one-piece Fins are smooth and burr-free, making them Easy To Clean. In heating and air conditioning projects, when the fin surface becomes cold, it is easy to wet and cool with water. In the case of heat exchange such as drying, heating, etc., the surface is anodized to provide beautiful color and gloss, which can effectively prevent surface corrosion. Aluminum rolled finned tubes are made of aluminum tubes in one piece. It has no-contact thermal resistance, high strength, thermal and mechanical shock, good thermal performance and a fairly expansive feather heat transfer surface. Heat exchangers with such finned tubes are located either in front of the light string or around the plate. Finned tube radiators not only have the inherent characteristics of large heat transfer, small temperature difference, small weight, small volume, and fast thermal response of heat pipes, but also should not affect the appearance of the room. According to the service life requirements, the fin radiator is not easy to be corroded and damaged, and has a long service life. High performance ratio, more durable, small footprint. The heat dissipation area of finned tube radiators can generally reach 100-20,000 square meters, which can be used in large heating systems such as workshops and workshops.

Finned Tubes are widely used in industrial production such as electric power and chemical industry. Many spiral heat transfer surfaces or threaded tubes can be considered as finned tubes. It has a significant effect on expanding the heat transfer area and promoting turbulence, and has a very large impact on single-phase heat transfer or phase change convective heat transfer. The structure of the finned tube heat exchanger is basically the same as that of the general shell and tube heat exchanger. Just use finned tube instead of normal tube as heat transfer surface. Finned tube heat exchangers are also commonly used to heat or cool the gas outside the tubes, and transfer steam or water in the tubes, such as air coolers, boiler economizers, radiators, etc. In order to improve the heat exchange efficiency, fins are usually added on the surface of the heat exchange tube to increase the external surface area (or internal surface area) of the heat exchange tube, so as to achieve the purpose of improving the heat exchange efficiency. This type of heat exchange tube is called finned tube Finned Tubes are divided into square finned tubes, spiral finned tubes, longitudinal finned tubes, spiral serrated finned tubes and inner finned Tubes according to their shape and structure; Finned tubes are divided into single-metal finned tubes and bimetallic composite finned tubes according to material; Finned Tubes can be divided into rolled finned tubes, welded finned tubes, roll-formed finned tubes and sleeve-formed finned tubes according to different processing technologies. Finned tube has many advantages, such as: 1. Strong heat transfer capability: Compared with the bare tube, the heat transfer area can be increased by 2-30 times, and the heat transfer coefficient can be increased by 1-2 times. application Finned tubes are widely used in electric power, chemical industry and other industries. Many spiral heat transfer surfaces or threaded tubes can be considered as finned tubes. It has a significant effect on expanding the heat exchange area and promoting turbulent flow, and has a greater effect on single-phase heat transfer and phase-change convective heat transfer. The structure of the finned tube heat exchanger is basically the same as the general shell and tube heat exchanger. Just use finned tubes instead of light tubes as the heat transfer surface. Finned tube heat exchangers are also commonly used for heating or cooling the gas outside the tube, and steam or water passes through the tube, such as air coolers, boiler economizers, radiators, etc. There are various materials for finned tubes, including Stainless steel, carbon steel, titanium copper alloy, etc. Industrial corrosion resistance is greatly improved.

Q: Why buy from us instead of from other suppliers? A: professional experience in process manufacturing, timely delivery and long-term after-sales service. High quality products fully meet any specific requirements. We provide one-stop solution services and competitive prices. Q: Are your products customized? A: Yes, we can customize new products according to your requirements or drawings. Q: what are your terms of payment? A: T / T, PayPal Q: how to ensure quality? A: before mass production, the final inspection is always carried out before shipment; Since the establishment of the company, it is our constant pursuit and commitment to meet our customers with science and technology and humanized services based on advanced science and technology as the starting point and the needs of customers. Finned Tube heat exchanger adopts the method of adding finned tube heat exchanger, which greatly improves the heat emission of radiator fins and further improves the role of heat emission of radiator fins. The finned tube heat exchanger is welded with low-carbon environment-friendly steel pipes, which is durable and emits heat for a long time. Our inspection and maintenance during use are still helpful to the service life of radiator fins.

Application Finned tubes are widely used in industries such as electric power and chemical industry. Many spiral heat exchange surfaces or threaded tubes can be regarded as finned tubes. It has a significant effect on expanding the heat transfer area and promoting turbulent flow, and has a great effect on single convective heat transfer and phase change convective heat transfer. The structure of finned tube heat exchanger is basically the same as that of general shell and tube heat exchanger. Just use finned tubes instead of bare tubes as the heat transfer surface. Finned tube heat exchangers are also commonly used to heat or cool gas outside the tube, and steam or water passes through the tube, such as air coolers, boiler economizers, radiators, etc. Finned tubes are made of a wide range of materials, such as stainless steel, carbon steel, titanium-copper alloy, etc., and the industrial corrosion resistance is greatly improved.

Product Categories : Non Standard Custom Finned Tube

Home > Products > Non Standard Custom Finned Tube > Laser Welding Steel Fin Tube Cooling Fins

Send Inquiry

Mr. Mike

Tel:+86-0510-85189125

Fax:

Mobile Phone:+8618851577799

Email:mike@cnmcway.com

Address:406, Henghua Science park, No.20, No.58, Xiuxi Road, Binhu District, Wuxi, Jiangsu

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.