Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Brand: MCWAY

Status: New

Warranty Period: 6 Months

Applicable Industry: Machinery Repair Shops, Food &Amp; Beverage Factory, Hotels, Food Shop, Energy &Amp; Mining, Construction Works, Other

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Hot Product 2019

Place Of Origin: China

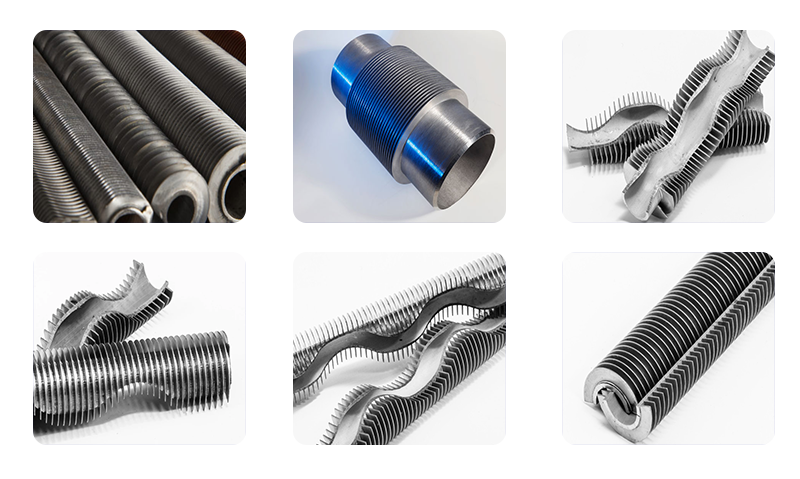

Types Of Parts: Finned Tube

Packaging: Wooden Box Packing

Transportation: Express,Air,Land,Ocean

Place of Origin: CHINA

Supply Ability: 50000meter/month

Port: Shang Hai,Ning Bo

Payment Type: Paypal,T/T

Incoterm: FOB,CFR,CIF,EXW,FCA,CIP

Advantages of Laser Welded Finned Tubes (welded spiral Tubes):

1. Most efficient:

Performs thermal calculations that do not have to involve added wire or its spatter, thus helping to improve heat transfer efficiency

2. Lighter:

Because the laser process does not use foreign welding wire, there is no added weight. Only fins or ribs and tubes

3. Full penetration of the weld:

Thanks to the laser process, the entire length of the fins and Tubes becomes "one-piece metal" because there is no added wire or shielding gas required for the welding process.

4. There is no gap between the fin and the tube wall:

There is no gap between the fin root and the tube wall, which can lead to crevice corrosion, which usually occurs in very tight crevices between two surfaces. Gaps can promote cold spots and thus corrosion.

5. Precise, no deformation welding:

The laser is precisely tuned and is not subject to interference from wires or shielding gas. Completely melts fin-to-pipe connections along the entire length of the fin

6. Better control of welding of dissimilar metals:

Precise adjustment for each application

7. Less Splash:

A cleaner and smoother surface will promote better heat transfer, less pressure drop and less chance of particle buildup, no matter how small the imperfection may seem.

8. Uniform root hardness:

Single and double-metal steel-aluminum composite Finned Tubes Aluminum rolled finned tubes are rolled from aluminum tubes as a whole, with no contact thermal resistance, high strength, thermal shock resistance and mechanical vibration resistance, good thermal expansion performance, and large expansion changes. By The hot surface Heat Exchanger made of such finned tubes is more efficient than serial fin or wound fin heat exchangers. Copper-aluminum composite finned tubes are laminated copper tubes and aluminum tubes to produce fins. They have the advantages of tight combination, small thermal resistance, good heat transfer performance, high strength, small flow loss, and Strong Corrosion Resistance. Under working conditions, it is not easily deformed and has a long service life. The overall rolled fins are smooth and free of burrs, no wrinkles, Easy To Clean , and easy to remove condensed water on the outer surface of the fins when heating and air conditioning projects are wet and cold, and are Not Easy To Accumulate Dust and scale. Drying and heating and other heat exchange occasions.

The string type is to string (carbon steel, copper, Stainless steel ) tubes (aluminum, copper, stainless steel) together, generally referring to the TLS type high-efficiency heat exchanger (commonly known as the surface cooler). Adopt advanced mechanical expansion tube and double-turned aluminum fin structure with bridge slot. The mechanical tube expansion makes the copper tube and aluminum fins in close contact, and the bridge gap promotes fluid turbulence, destroys the boundary layer, and improves the heat transfer coefficient. The advanced structural form, coupled with the reasonable design of waterway stroke, pipe distance and plate distance, make the heat exchanger have the characteristics of good heat transfer performance, small wind resistance, compact structure and light weight. Air Heater Laser Welded Finned Tubes

Laser Welded Finned Tube (stainless steel welded Tube) properties:

1. Thin and continuous weld

2. Small heat affected zone

3. Welding parts with only slight discoloration

4. Tubes and fins with only slight microstructural changes

5. High utilization rate of forming heat energy

6. Increased safety due to avoidance of crevice corrosion due to high weld integrity between tube and fin

7. The welding seam is free of impurities, because laser welding is carried out under a protective atmosphere

There are many kinds of laser welded finned tubes in use. In operation, High Frequency Welded Finned Tubes are mainly used. Although it is more advanced in product quality and production automation compared with inlay and brazing methods, it is difficult to weld the root of high-frequency welded finned tubes and there are wrinkles at the root, resulting in many shortcomings in heat exchange efficiency and convenient ash deposition prevention. In view of the above reasons and in response to the guidelines and policies on energy conservation and emission reduction.

Technology of laser welding Finned Tube

1. The thickness of the base Tube of the Laser Welded Fin Tube can be 0.8-1.5 mm, and the thickness of the fin can be 0.3-1 mm, which greatly saves the material cost compared with other processes.

2. High Penetration Rate can prevent gap corrosion, prolong service life and reduce heat transfer resistance.

3. Break through the material limit and use different materials for processing.

4. It is easy for secondary processing and can be directly used for coil and elbow.

5. The welding heat affected zone is small and the metallographic change is small, which makes the processing of small diameter finned tube possible.

Application and material of Finned Tube.Steel Aluminum Composite Radiator

Finned Tubes are widely used in electric power, chemical and other industries. Many helical heat transfer surfaces or threaded Tubes can be considered Finned Tubes. It has a significant effect on expanding the heat exchange area and promoting turbulent flow, and has a great effect on single-phase heat transfer and phase change convective heat transfer. The structure of the Finned Tube Heat Exchanger is basically the same as that of the general shell and tube heat exchanger. Just use Finned Tubes instead of bare tubes as heat transfer surfaces. Finned Tube heat exchangers are also commonly used to heat or cool gas outside the tubes, steam or water passing through the Tubes, such as air coolers, boiler economizers, radiators, etc.

There are many types of finned tubes, and new varieties are emerging continuously. It can generally be classified according to the following aspects:

1. Classified by processing technology

2) Welding and forming Finned Tubes (high frequency welded Finned Tubes, submerged arc welded Finned Tubes);

3) Roll-formed Finned Tubes;

4) Finned tube installation and forming;

5) Cast Finned Tubes;

6) Tension wound finned tube;

7) Insert the tube.

Classified by fin shape

1) square finned tube (square finned tube);

2), circular Fin Tube;

3) Spiral finned tubes (spiral finned tubes);

4) Longitudinal finned tubes (longitudinal finned tubes)

5) corrugated finned tube;

6) Spiral serrated finned tube;

7) Needle finned tube;

8) Inner finned tube (Inner finned tube). etc.

For more details, please contact us.

Finned Tube has a wide range of materials, including stainless steel, carbon steel, titanium copper alloy and so on. Industrial corrosion resistance is greatly improved.Cold Rolled Finned Tubes

Reasons to choose us:

We are one of the industry finned tube manufacturers in China, our products have been sold all over the world for many years, and have been highly appraised by customers all over the world. We have a complete service team, complete production equipment and strict quality management system to ensure your procurement needs and transaction security in all aspects. We guarantee that every product delivered is qualified. When you contact us to inquire about your order, we will have professional technical engineers to conduct detailed docking with you on technical issues to ensure that the products meet your needs. Our sales managers are on call 24 hours a day to ensure prompt and efficient service.

Product Categories : Non Standard Custom Finned Tube

Home > Products > Non Standard Custom Finned Tube > Carbon Steel Stainless Steel Laser Welded Finned Tubes

Send Inquiry

Mr. Mike

Tel:+86-0510-85189125

Fax:

Mobile Phone:+8618851577799

Email:mike@cnmcway.com

Address:406, Henghua Science park, No.20, No.58, Xiuxi Road, Binhu District, Wuxi, Jiangsu

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.