Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Brand: MCWAY

Status: New

Warranty Period: 6 Months

Applicable Industry: Food &Amp; Beverage Factory, Machinery Repair Shops, Manufacturing Plant, Hotels, Other, Energy &Amp; Mining, Construction Works

Out-of-warranty Service: Spare Parts, Online Support, Video Technical Support

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Hot Product 2019

Place Of Origin: China

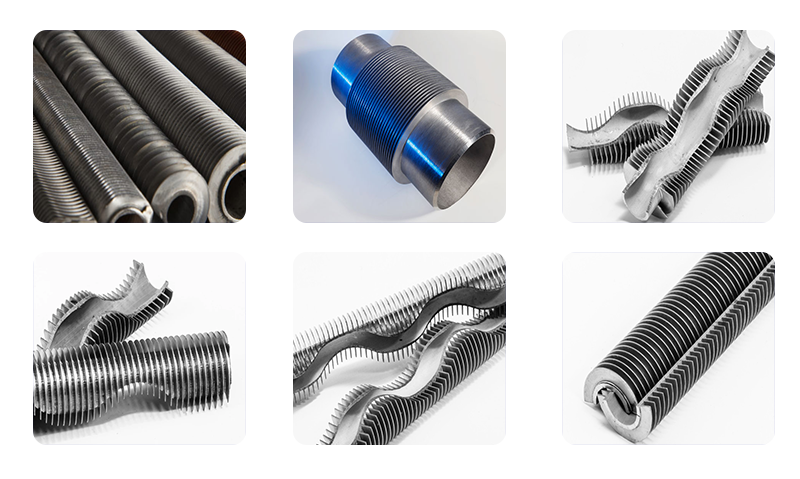

Types Of Parts: Finned Tube

Packaging: Wooden box packaging

Transportation: Ocean,Land,Air,Express,others

Place of Origin: CHINA

Supply Ability: 50000meter/month

Port: ShangHai,NingBo

Payment Type: T/T,Paypal

Incoterm: FOB,CFR,CIF,EXW,FCA,CIP

The aluminum-rolled Finned Tubes and copper-aluminum composite finned tubes produced by our factory are all anodized on the surface, and the color is beautiful and generous, which can effectively prevent surface corrosion. Our factory can also process steel winding finned tubes and steel-aluminum composite finned tubes according to the needs of users. Aluminum rolled Finned Tube specifications and performance table outer diameter D (mm) root diameter d (mm) fin height h (mm) fin thickness s (mm) fin pitch t (mm) tube wall thickness (mm) cooling area sw (m2/m) finning ratio a (sw/sn) weight (kg/m) service temperature (°C)

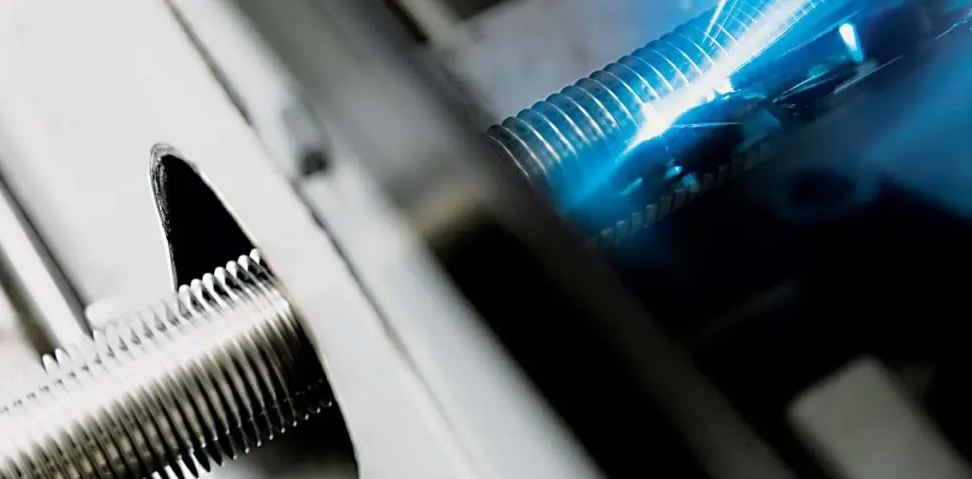

High performance 304 Laser Finned Tubes

The string type is to string (carbon steel, copper, Stainless steel ) tubes (aluminum, copper, stainless steel) pieces together, generally referring to TLS type high-efficiency heat exchangers (commonly known as surface coolers). It adopts the advanced mechanical expansion tube and bridge-type slit double-turned aluminum fin structure. High Performance 304 Laser Finned Tubes

The mechanical tube expansion makes the copper Tube and the aluminum fins in close contact, and the bridge-type slit can promote fluid turbulence, destroy the boundary layer, and improve the heat transfer coefficient. The advanced structural form, coupled with the reasonable design of the waterway stroke, the tube distance and the plate distance, make the Heat Exchanger have the characteristics of good heat transfer performance, small air resistance, compact structure and light weight.

Finned tube radiators can be made of steel pipes, stainless steel pipes, steel-aluminum composite pipes, copper-aluminum composite pipes, etc., with various materials, and different materials can be used according to the needs of users.

High Performance 304 Laser Finned Tubes.

The Steel Finned Tube radiator for boiler is a new type of heat dissipation and heating equipment in recent years. Based on the traditional radiator, the processing technology is further upgraded. By adding finned tubes, the heat dissipation efficiency of the radiator is improved, and the heat dissipation effect of the radiator is improved. It has become a good substitute for the traditional radiator and a good choice for winter heating equipment in large areas. The steel finned tube radiator has high dustproof performance to prevent dust accumulation and is Easy To Clean . The surface of the Fin Tube radiator will be carefully polished during processing and manufacturing to ensure that the surface of the radiator is smooth and free of thorns, so the dust is not easy to accumulate, and the surface temperature of the radiator is high, so the dust is not easy to coke. When there is dust on the surface of the radiator, gently wipe it with a wet wiping cloth. The Finned Tube radiator uses steam and heat transfer oil as the heat transfer medium. Its heating temperature is higher, and the fluidity of steam and heat transfer oil is better, so its heating efficiency is higher. As the heat transfer medium, steam and heat transfer oil are often used in large workshops and greenhouses, with excellent heating effect.

A copper-aluminum composite pipe is proposed to replace the traditional copper pipe used in the heat exchanger of the outdoor unit of the air conditioner, which can reduce the cost by 27.8%. Firstly, the heat transfer and flow performance of the copper-aluminum composite tube and copper tube Finned Tube Heat Exchanger with a diameter of Φ7 were studied by numerical simulation. Compared with the heat exchanger with copper tubes, the pressure distribution on the air side of the heat exchanger with copper-aluminum composite tubes is almost unchanged, and the heat transfer capacity is reduced by 3.12%, which has little impact on performance.

The Finned Tube heat exchanger adopts the method of adding laser welding finned tubes, which greatly improves the heat transfer efficiency, has Strong Corrosion Resistance, longer service life, wider temperature range, high pressure resistance, and conforms to the national energy conservation and environmental protection emission standards, etc.

Finned Tube heat exchangers are essential machines and equipment in overall heat transfer in industrial manufacturing. It is widely used in heat exchanger industries in petroleum refining, chemical industry, medicine, food, power plants, new energy, boilers, nuclear power and other fields. In recent years, in view of the development trend of new technology application and new energy development, improving the performance of heat exchangers has been paid more and more attention by the industrial field.

Wuxi Mcway Equipment Technology Co., Ltd. is a high-tech enterprise integrating R & D, production and sales. The company develops and produces Laser Welded Finned Tubes and Laser Welded Finned Tube Heat Exchanger. The base pipe materials are carbon steel, stainless steel, alloy steel, copper tube, titanium tube and nickel tube; The fin strip is made of carbon steel, stainless steel, alloy steel, copper and titanium; Our company also has the ability to produce high-frequency welded Finned Tubes, Extruded Finned Tubes, embedded G-type finned tubes, wound L / LL/ KL type finned tubes and Low Finned Tubes, and can be customized into cylindrical and disk shapes according to customer requirements.

The company has strong technical force, complete production equipment, advanced production technology, perfect detection means, reliable and Stable quality, and has passed the IS09001 international quality system certification. Guided by customer demand, the company can customize heat conversion products and heat energy schemes according to customer demand; The company continues to improve the quality of products, and is committed to serving petroleum, chemical industry, pharmacy, food, power plant, metallurgy, textile printing and dyeing, new energy, shipbuilding, military industry, boiler, HVAC refrigeration, waste heat recovery and other fields, so as to provide High Quality thermal energy solutions and services for the global thermal energy industry.

What factors does the film management need to have a grasp of? Although it is said that with laser-welded stainless steel finned tubes, people don't have to worry too much about heating factors, but they still need to master some factors in order to use them better.

Many users will feel that the room temperature is still not up to standard after installing the steel plate radiator. This is a problem that many heating users in winter worry about. So what factors will affect the indoor heating temperature?

1. Do not install a heating cover during decoration, so as not to affect the heat dissipation effect of the heating. If the heating cover has been installed and cannot be removed, you need to open the cooling cover. If opening will affect the appearance, you can turn the cooling cover upside down and use it with the louvers facing upwards, so that the heat inside the heating cover can be released.

2. The lack of heat in the early stage of heating is mostly caused by air blockage, because at the beginning of heating, the pipes are actually a mixture of water and air, and if the air is not exhausted completely, air blockage will occur and affect the water cycle. Citizens should pay attention to heating in time 3. Ensure ventilation 2 to 3 times a day, 5 to 10 minutes each time, open all doors and windows when ventilating, and realize air exchange in a short time. Not only the ventilation effect of the pipe is not obvious, but also the heat will be lost, especially when the radiator is under the window, this waste will be more serious.

4. Generally speaking, when the temperature is the same, humid air is more likely to make people feel warmer than dry air, so green plants or humidifiers can be used to keep the air moist, and the humidity is preferably 35% to 70%.

5. The temperature of the water supply in the heating pipe network is low, which will lead to low temperature of the radiator.

6. The insulation effect of the house is not good. For example, the walls, doors and windows are made of non-energy-saving materials, and the heat transfer coefficient is high; the doors and windows are in disrepair for a long time, the seal is not tight, and the cold air seeps too much; the doors and windows are often opened and closed, and the heat loss is large.

7. Changes in the room area due to interior decoration and changes in the structure of the house; changes in heating facilities, such as changing the position of the radiator, increasing the area of the radiator, changing the heating method of the radiator, covering the radiator, etc., will cause the operation of the heating pipe network to fail. If the situation changes, it will affect the heat dissipation of the radiators, cause heating imbalance, and even affect other residents in the unit building.

8. The indoor pipe network has been in disrepair for a long time, and the rust in the pipe is blocked, which will seriously affect the hot water circulation and cause the indoor temperature to not go up, especially on the first floor.

Product Categories : Non Standard Custom Finned Tube

Home > Products > Non Standard Custom Finned Tube > Laser Welding 304 Finned Tube For New Energy

Send Inquiry

Mr. Mike

Tel:+86-0510-85189125

Fax:

Mobile Phone:+8618851577799

Email:mike@cnmcway.com

Address:406, Henghua Science park, No.20, No.58, Xiuxi Road, Binhu District, Wuxi, Jiangsu

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.