Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Status: New

Warranty Period: 6 Months

Applicable Industry: Food &Amp; Beverage Factory, Machinery Repair Shops, Manufacturing Plant, Hotels, Energy &Amp; Mining, Construction Works, Other

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Hot Product 2019

Place Of Origin: China

Types Of Parts: Finned Tube

Packaging: Wooden box packaging

Transportation: Air,Land,Ocean,Others

Supply Ability: 50000meter/month

Port: Shang Hai,Ning Bo

Payment Type: Paypal,T/T

Incoterm: EXW,CIF,CFR,FOB,FCA,CIP

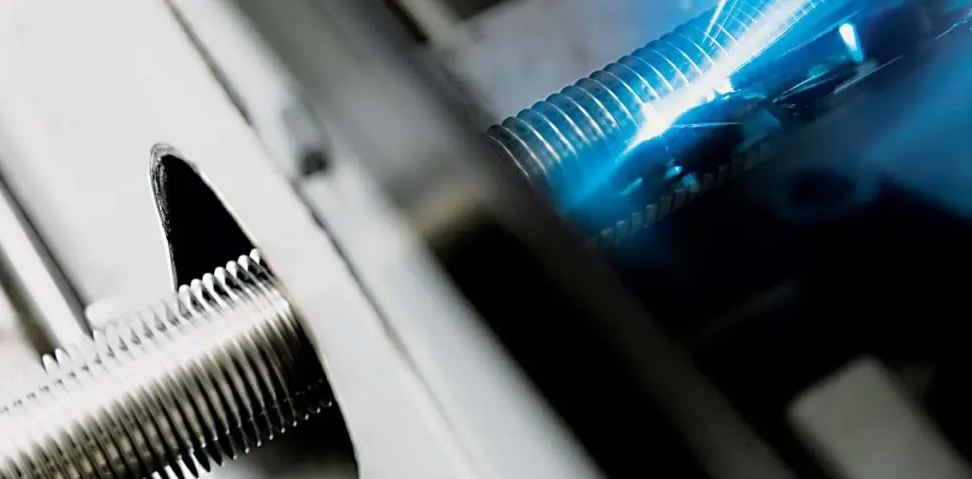

The Laser Welded Spiral Finned Tube is a new type, wear-resistant and efficient heat exchange material in the Finned Tube welding industry. It is also a high-efficiency energy-saving heat exchange element, which has the characteristics of high heat exchange efficiency, large heat dissipation area, long service life, wide temperature range, high pressure resistance, and compliance with national energy conservation and environmental protection emission standards. Now it is widely used in petroleum refining, chemical industry, medicine, food, power plant, boiler, nuclear power, ship, military industry, drying and refrigeration and other industries. The range of materials for Finned Tubes is very wide, including Stainless steel , carbon steel, titanium, copper, alloys, etc., and the degree of corrosion resistance is greatly increased.

Laser Welded Finned Tube is a combination of Spiral Finned Tube laser welding technology, hardware mold, and numerical control automatic control, which can realize welding between different metals (carbon steel, stainless steel, and any single metal combination welding), easy to operate, and easy to manufacture Flexible and convenient. Overcome a series of problems such as fracture, slow speed, poor forming, and wrinkling of finned tubes during the welding process. Now the company has successfully mastered everything in the welding of finned tubes such as spiral finned tubes and heat exchangers. Production and coordination of parameters and automatic fixtures. Plate Heat Exchanger mainly includes: high heat exchange efficiency and high waste heat recovery rate; Small floor area; Low cost; Small floor space and so on, which are advantages over tubular heat exchanger. Heat exchanger manufacturers mainly use the heat energy that will and may be wasted in industrial production to recycle and reuse it. In this respect, the manufacturer is also constantly innovating and improving. The flue gas waste heat recovery device is based on the common heat exchanger, combined with the current situation of energy shortage in the market and the consideration of environmental protection, how to recover and purify waste water and waste gas, including flue gas waste heat, is the precondition for the emergence of waste heat recovery device. 2、 Waste water waste heat recovery device Many users call it: wide channel sewage heat exchanger, wide channel heat exchanger. As there are many impurities in the waste water, the plate heat exchanger or tubular heat exchanger shall be selected for waste heat recovery according to the chemical properties of the heat exchange medium and the content of impurities.

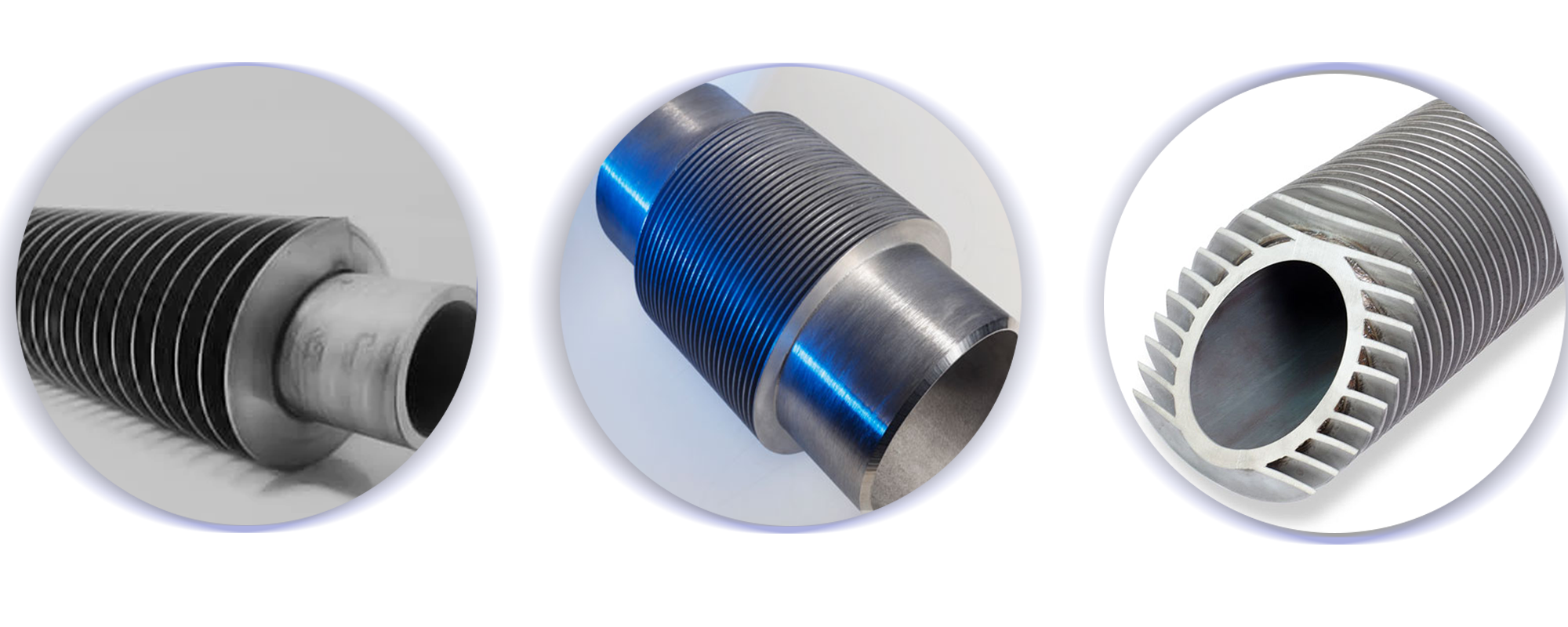

Finned tubes, also known as heat sinks, are divided into single-metal finned tubes and bimetallic finned tubes. Single metal finned tubes are rolled from aluminum tubes as a whole, called aluminum rolled finned tubes, have no contact thermal resistance, high strength, heat resistance and mechanical vibration, good thermal expansion performance, and have a considerable extended heat transfer surface. The heat exchanger made of this kind of Fin Tube is more effective than the serial fin or wound fin heat exchanger, and it is a heat exchanger with a wide range of uses. Single metal finned tubes can also be made by direct rolling of steel tubes or copper tubes. Bimetal composite finned tubes are divided into steel-aluminum composite finned tubes and copper-aluminum composite finned tubes. Steel-aluminum composite finned tubes are made of (steel tubes, aluminum tubes; or stainless steel tubes, aluminum tubes) and then rolled out of fins, copper-aluminum composite finned tubes are made of (copper tubes, aluminum tubes) and then rolled The fins produced have the advantages of tight combination, small thermal resistance, good heat transfer performance, high strength, small flow loss, strong anti-corrosion performance, not easy to deform under long-term cold and hot conditions, and long working life. The overall rolled fin has no burr, no wrinkle, Easy To Clean , easy to remove condensed water on the outer surface of the fin during wet cooling in heating and air conditioning engineering, and not easy to dust and scale in drying heating and other heat exchange occasions. The surface of the monometallic finned tubes and bimetallic composite finned tubes produced by our factory is anodized, the color is beautiful and generous, and it can effectively prevent surface corrosion. Low-finned tubes are mainly used in condenser tubes and evaporators in air-conditioning and refrigeration equipment, absorption refrigerators, oil coolers and various other heat exchangers; Evaporators, condenser tubes and evaporators in marine exchangers; used in gas turbine units and petrochemical air coolers, diesel coolers, secondary coolers and various heat exchangers in waste heat recovery systems, used in the chemical industry dryers and heaters. Specializing in the production of single metal finned tubes and bimetallic composite finned tubes, welcome to customize the detailed description: Steel-aluminum composite Finned Tubes are integrally rolled from steel tubes and aluminum tubes, with small thermal resistance, high strength, thermal and mechanical shock resistance, good heat transfer performance, and considerable extended heat transfer surface. The heat exchanger made of tubes is more effective than the serial sheet or wound sheet heat exchanger. Copper-aluminum composite finned tubes are copper and aluminum tubes that are laminated and then rolled out of fins. They have the advantages of tight combination, small thermal resistance, good heat transfer performance, high strength, small flow loss, and Strong Corrosion Resistance. It is not easy to deform under working conditions and has a long working life. The overall rolled fins are smooth and free of burrs, no wrinkles, easy to clean, easy to remove condensed water on the outer surface of the fins during wet cooling in heating and air conditioning projects, and not easy to dust and scale in drying heating and other heat exchange occasions. The steel-aluminum composite finned tubes and copper-aluminum composite Finned Tubes produced by our factory are all anodized on the surface, and the color is beautiful and generous, which can effectively prevent surface corrosion. According to the needs of users, our factory can also process finned tubes of winding fins and serial fins.

Q: Why buy from us instead of from other suppliers? A: professional experience in process manufacturing, timely delivery and long-term after-sales service. High quality products fully meet any specific requirements. We provide one-stop solution services and competitive prices. Q: Are your products customized? A: Yes, we can customize new products according to your requirements or drawings. Q: what are your terms of payment? A: T / T, PayPal Q: how to ensure quality? A: before mass production, the final inspection is always carried out before shipment; Since the establishment of the company, it is our constant pursuit and commitment to meet our customers with science and technology and humanized services based on advanced science and technology as the starting point and the needs of customers. Finned Tube Heat Exchanger adopts the method of adding finned tube heat exchanger, which greatly improves the heat emission of radiator fins and further improves the role of heat emission of radiator fins. The finned tube heat exchanger is welded with low-carbon environment-friendly steel pipes, which is durable and emits heat for a long time. Our inspection and maintenance during use are still helpful to the service life of radiator fins.

About Finned Tubes Laser Welded Finned Tubes in which the fins (solid or serrated) are helically wound and continuously welded to the tube by a fully automatic laser fin machine. Produced in strict accordance with enterprise standards, with sophisticated technology, excellent performance, lower heat input, and improved heat flow efficiency and corrosion resistance. A finned tube is a tube with many fins around the outer surface. These fins act as filters and mechanisms to transfer heat from the material inside the tube to the outside space and vice versa. Finned Tubes are used in applications that require the transfer of heat from a hot fluid to a cooler fluid through the tube walls. ♦ Laser Welded Finned Tube ♦ High Frequency Welded Finned Tube

Product Categories : Non Standard Custom Finned Tube

Home > Products > Non Standard Custom Finned Tube > Laser Welding High Frequency Welding Finned Tube

Send Inquiry

Mr. Mike

Tel:+86-0510-85189125

Fax:

Mobile Phone:+8618851577799

Email:mike@cnmcway.com

Address:406, Henghua Science park, No.20, No.58, Xiuxi Road, Binhu District, Wuxi, Jiangsu

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.