Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Status: New

Warranty Period: 6 Months

Applicable Industry: Hotels, Food &Amp; Beverage Factory, Machinery Repair Shops, Manufacturing Plant, Other, Construction Works, Energy &Amp; Mining

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Hot Product 2019

Place Of Origin: China

Types Of Parts: Finned Tube

Packaging: Wooden box packaging

Transportation: Ocean,Land,Air,Express

Supply Ability: 50000meter/month

Port: Shang Hai,Ning Bo

Payment Type: Paypal,T/T

Incoterm: FCA,CIP,EXW,CIF,CFR,FOB

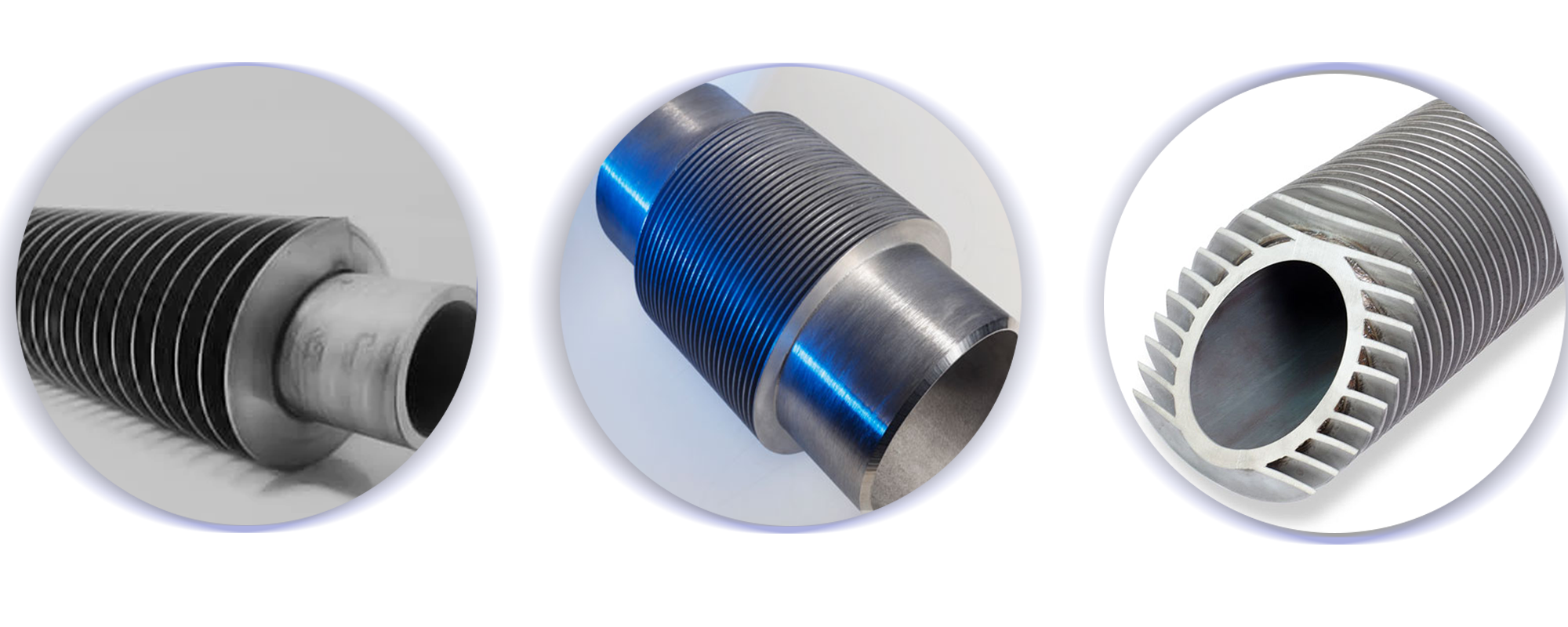

Extruded Finned Tube

Rolled Finned Tube fins are smooth, burr-free, wrinkle-free, beautiful and bright, and Easy To Clean . When used as components of air heaters and surface coolers, it is easy to remove surface condensation water, and it is Not Easy To Accumulate Dust and condensation in drying and heating and other occasions. Scale, rolled finned tube fins cross-section and trapezoidal, so the fins have high strength, and expand the heat dissipation surface, so that the material can be used to the greatest extent.

The single-metal rolled finned tube is rolled from an aluminum tube as a whole, has no contact resistance, is resistant to thermal shock and mechanical shock, has good thermal expansion performance, and has a considerable extended heat transfer surface. The finned tube made of this All kinds of heat exchangers and heaters are obviously better than radiators made of serial fins, winding fins and cast iron.

Double-metal aluminum rolled finned tube is to put the aluminum tube tightly on the base tube, and then go through multiple processes such as rough rolling and finishing rolling on the aluminum tube, and finally roll out high-quality Finned Tubes . The double-metal finned tube produced by our factory The metal aluminum rolled finned tube has good heat transfer performance, and the finned tube and the base tube will not undergo electrochemical corrosion during use.

Compared with the ordinary wound finned tube, the contact thermal resistance changes with temperature in It remains Stable in a large range, so the heat transfer performance of the bimetallic aluminum rolled finned tube is more stable than that of the coiled finned tube in the limit tube wall temperature range. In addition, compared with the coiled tube, the bimetallic aluminum rolled tube has outstanding corrosion resistance and high strength. It can withstand 4.0MPa water pressure cleaning, and the fins still do not fall down. The tube can be selected according to the corrosion of the fluid in the tube and the processing technology, and the base tube can be selected from carbon steel, copper, Stainless steel, etc.

3. Sequential Finned Tube

The string type is to string (carbon steel, copper, stainless steel) tubes (aluminum, copper, stainless steel) sheets, generally referring to TLS type high-efficiency heat exchangers (commonly known as surface coolers). It adopts the advanced mechanical expansion tube and double-pass aluminum fin structure with bridge-type slits. The mechanical tube expansion makes the copper tube and the aluminum fins in close contact, and the bridge-type slit can promote fluid turbulence, destroy the boundary layer, and improve the heat transfer coefficient.

New Energy Laser Welding Fin Tube .The advanced structural form, coupled with the reasonable design of the waterway stroke, the tube distance and the plate distance, make the Heat Exchanger have the characteristics of good heat transfer performance, small air resistance, compact structure and light weight. It can be widely used in air conditioning, cooling, dehumidification, heating and other projects. It is an ideal accessory product for fresh air units and air handling units. It can also be connected with air ducts for cooling or heating alone. 3. lightweight The reason is that it is compact and mostly made of aluminum alloys, and now steel, copper, composite materials, etc. have also been mass-produced. 4. Strong adaptability The Finned Tube Heat Exchanger can be applied to: gas-gas, gas-liquid, liquid-liquid, heat exchange between various fluids, and phase change heat that occurs when the set state changes. Through the arrangement and combination of flow channels, it can adapt to different heat exchange conditions such as countercurrent, cross-flow, multi-stream, multi-pass flow, etc. The heat exchange needs of large-scale equipment can be met through the combination of series, parallel, and series-parallel between units. In industry, it can be stereotyped and mass-produced to reduce costs, and expand interchangeability through building block combinations.

Q: Why buy from us instead of from other suppliers?

A: Rofessional experience in process manufacturing, timely delivery and long-term after-sales service. High quality products fully meet any specific requirements. We provide one-stop solution services and competitive prices.

Q: Are your products customized?

A: Yes, we can customize new products according to your requirements or drawings.

Q: What are your terms of payment?

A: T / T, PayPal

Q: How to ensure quality?

A: Before mass production, the final inspection is always carried out before shipment;

Since the establishment of the company, it is our constant pursuit and commitment to meet our customers with science and technology and humanized services based on advanced science and technology as the starting point and the needs of customers.

The processing technology of steel aluminum composite Finned Tube is to first process the double metal composite tube on the aluminum tube and copper tube, and then, after mechanical cold rolling, make use of the physical characteristics of aluminum tube, and use the tube centered on the steel tube and the fin tube closely combined with the aluminum needle made by cold rolling. When the steel aluminum composite fin tube radiator is wet cooled in the heating and air-conditioning project, it is easy to remove the condensation water on the external surface of the fin, and it is not easy to produce dust and dirt in the drying heating and other heat exchanges.

2. Characteristics of steel aluminum composite finned tube:

1. Solid combination, small thermal resistance and good heat transfer performance.

High strength and small flow loss.

3. It has strong anti-corrosion performance, is not easy to deform under long-term cold and hot conditions, and has a long service life.

3: Structural diagram of steel aluminum composite finned tube:

4. Performance table of steel aluminum composite Finned Tube specification:

Finned Tube radiator (radiator, also known as heat discharge, air heater and air heat exchanger) is the main equipment of heat exchanger, including cooling air with refrigerant, heating air with heat medium or recovering air waste heat with cold water. Access

Warm water, steam or high-temperature heat transfer oil can heat the air, and salt water or low-temperature water can be used to cool the air.

The heat exchanger is a very good energy-saving equipment, which can reuse the energy that would otherwise be wasted. The finned tube heat exchanger is a member of the heat exchanger family. Some working principles of fin-tube heat exchangers and its characteristics are convenient for everyone to have a better understanding of fin-tube heat exchangers.

The principle of finned tube heat exchanger - the characteristics of finned tube heat exchanger

1. High heat transfer efficiency Because the disturbance of the fin to the fluid causes the boundary layer to break continuously, so it has a large heat transfer coefficient; at the same time, because the separator and fin are very thin and have high thermal conductivity, the finned tube heat exchange The device can achieve High Efficiency.

2. Compact Because the finned tube heat exchanger has an expanded secondary surface, its specific surface area can reach 1000㎡/m3.

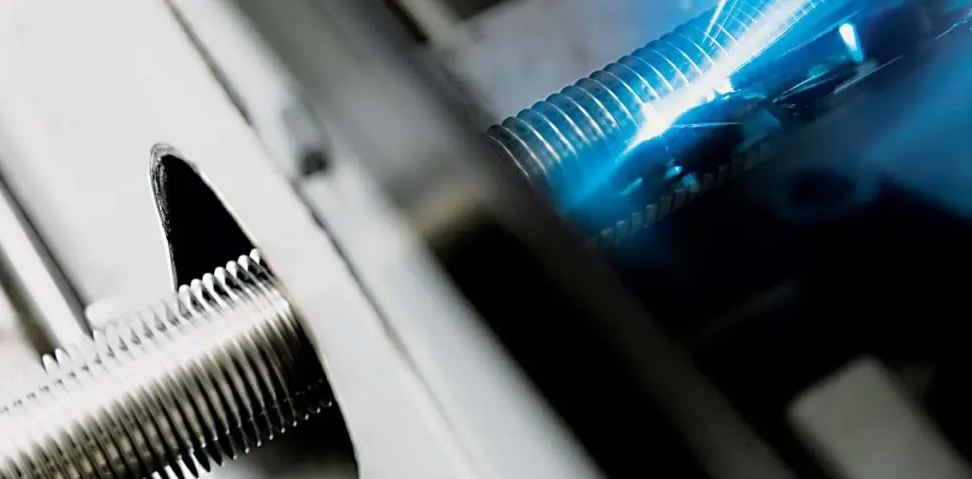

Advantages of Laser Welded Finned Tubes

1. The degree of automation is high. The automatic fin laser welding machine can complete the welding at one time, and the synchronous winding makes the fin foot and the pipe deeply welded.

2 Laser welding, high firmness, strong bonding force. Laser welding is a metallurgical combination, and the welding strength is greater than 600MPa.

3. High-precision laser welding machine, welding 8-meter-long finned tubes, with an accuracy of 0.05mm.

4. Laser welding can greatly improve the heat transfer coefficient.

5. The length of the laser-welded fin section is less than or equal to 2.5mm, and the heat dissipation area is nearly 50% larger than that of the high-frequency welded pipe (the distance is greater than or equal to 4.5mm), which greatly reduces the material of the pipe and can also reduce the change in the volume of the heat exchanger.

Wuxi Mcway Equipment Technology Co., Ltd. is a high-tech enterprise integrating R & D, production and sales. The company develops and produces laser welded Finned Tubes and Laser Welded Finned Tube Heat Exchanger. The base pipe materials are carbon steel, stainless steel, alloy steel, copper tube, titanium tube and nickel tube; The fin strip is made of carbon steel, stainless steel, alloy steel, copper and titanium; Our company also has the ability to produce high-frequency welded Finned Tubes, Extruded Finned Tubes, embedded G-type finned tubes, wound L / LL/ KL type finned tubes and Low Finned Tubes, and can be customized into cylindrical and disk shapes according to customer requirements.

The company has strong technical force, complete production equipment, advanced production technology, perfect detection means, reliable and stable quality, and has passed the IS09001 international quality system certification. Guided by customer demand, the company can customize heat conversion products and heat energy schemes according to customer demand; The company continues to improve the quality of products, and is committed to serving petroleum, chemical industry, pharmacy, food, power plant, metallurgy, textile printing and dyeing, new energy, shipbuilding, military industry, boiler, HVAC refrigeration, waste heat recovery and other fields, so as to provide High Quality thermal energy solutions and services for the global thermal energy industry.

Reasons to choose us:

We are one of the finned tube manufacturers in China, and our products have been sold well all over the world for many years, and have been highly praised by customers all over the world. We have a complete service team, complete production equipment and strict quality management system to fully guarantee your procurement needs and transaction security. We ensure that every product delivered is qualified. When you contact us to inquire about your order, we will have professional technical engineers to conduct detailed docking with you on technical issues to ensure that the products meet your needs. Our sales managers are on call 24 hours a day to ensure timely and efficient service.

Product Categories : Non Standard Custom Finned Tube

Home > Products > Non Standard Custom Finned Tube > Laser Welded Finned Tube For New Nnergy Drying

Send Inquiry

Mr. Mike

Tel:+86-0510-85189125

Fax:

Mobile Phone:+8618851577799

Email:mike@cnmcway.com

Address:406, Henghua Science park, No.20, No.58, Xiuxi Road, Binhu District, Wuxi, Jiangsu

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.