Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Brand: MCWAY

Status: New

Warranty Period: 6 Months

Applicable Industry: Hotels, Food &Amp; Beverage Factory, Machinery Repair Shops, Manufacturing Plant, Construction Works, Energy &Amp; Mining, Other

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Hot Product 2019

Place Of Origin: China

Types Of Parts: Finned Tube

Packaging: Wooden box packaging

Transportation: Ocean,Land,Air,Express,Others

Place of Origin: CHINA

Supply Ability: 50000meter/month

Port: Shang Hai,Ning Bo

Payment Type: T/T,Paypal

Incoterm: FOB,CFR,CIF,EXW,FCA,CIP

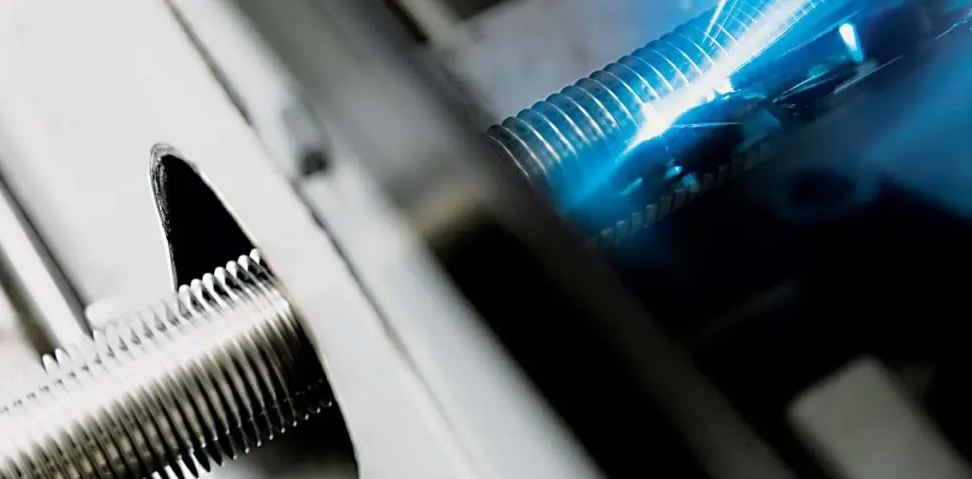

There are many kinds of Laser Welded Finned Tubes in use. In operation, high-frequency welded Finned Tubes are mainly used. Although it is more advanced in product quality and production automation compared with inlay and brazing methods, it is difficult to weld the root of high-frequency welded finned tubes and there are wrinkles at the root, resulting in many shortcomings in heat exchange efficiency and convenient ash deposition prevention. In view of the above reasons and in response to the guidelines and policies on energy conservation and emission reduction.

Technology of laser welding Finned Tube

1. The thickness of the base tube of the laser welded Fin Tube can be 0.8-1.5 mm, and the thickness of the fin can be 0.3-1 mm, which greatly saves the material cost compared with other processes.

2. High Penetration Rate can prevent gap corrosion, prolong service life and reduce heat transfer resistance.

3. Break through the material limit and use different materials for processing.

4. It is easy for secondary processing and can be directly used for coil and elbow.

5. The welding heat affected zone is small and the metallographic change is small, which makes the processing of small diameter finned tube possible.

Application and material of Finned Tube Finned Tubes are widely used in electric power, chemical and other industries. Many helical heat transfer surfaces or threaded Tubes can be considered finned tubes. It has a significant effect on expanding the heat exchange area and promoting turbulent flow, and has a great effect on single-phase heat transfer and phase change convective heat transfer. The structure of the Finned Tube Heat Exchanger is basically the same as that of the general shell and tube Heat Exchanger. Just use finned tubes instead of bare tubes as heat transfer surfaces. Finned tube heat exchangers are also commonly used to heat or cool gas outside the tubes, steam or water passing through the tubes, such as air coolers, boiler economizers, radiators, etc. , Finned tube has a wide range of materials, including Stainless steel, carbon steel, titanium copper alloy and so on. Industrial corrosion resistance is greatly improved.Cold Rolled Finned Tubes

The heat exchanger is a very good energy-saving equipment, which can reuse the energy that would otherwise be wasted. The finned tube heat exchanger is a member of the heat exchanger family. Some working principles of fin-tube heat exchangers and its characteristics are convenient for everyone to have a better understanding of fin-tube heat exchangers. The principle of finned tube heat exchanger - the characteristics of finned tube heat exchanger 1. High heat transfer efficiency Because the disturbance of the fin to the fluid causes the boundary layer to break continuously, so it has a large heat transfer coefficient; at the same time, because the separator and fin are very thin and have high thermal conductivity, the finned tube heat exchange The device can achieve High Efficiency. 2. Compact Because the finned tube heat exchanger has an expanded secondary surface, its specific surface area can reach 1000㎡/m3.

Application of Finned Tube The application of Finned Tubes is very extensive now. Its main purpose is heat exchange, so it is mainly installed on the surface of heat exchange Tubes to improve heat exchange efficiency. However, for finned tubes, there are still certain requirements on its performance, mainly including wear resistance, stability, etc., especially when used in harsh environments, its performance requirements are better, and it also has lower Contact thermal resistance. and good dustproof performance. What principles should be followed when using finned tubes for heat transfer? (1) If the heat transfer coefficients on both sides of the tube differ greatly, the finned tube should be installed on the smaller side. (2) If the heat transfer coefficient on both sides of the tube is small, you can install finned tubes on both sides, but don't install it on one side only, the effect is not good. (3) If the heat transfer coefficient on both sides of the tube is large, finned tubes should not be installed.

The Finned Tube is a heat exchange element when put into operation. To some extent, it is to further improve the heat transfer efficiency. In most cases, the effect of improving heat exchange efficiency can be achieved by adding fins on the outer surface of the heat exchange tube and enlarging the total area of the outer surface of the heat exchange tube. As a heat exchange element, finned tubes work under high-temperature industrial waste gas conditions for a long time. For example, the application environment of finned tubes in boiler heat exchangers is harsh, high temperature, high pressure, and corrosive environment, and finned tubes need to have High performance parameters. Finned tubes have high corrosion resistance during use; in fact, many times, when we usually work on an item, the application of finned tubes basically reflects its unique environmental protection advantages, adding a lot of additional It also improves the application functions on the basis of the original facilities, which is more convenient for the use of scenes in daily life. Wear resistance is also a distinct feature of finned tubes. In the assembly process of certain parts, the wear resistance of finned tubes will always help the application of equipment durability. Some necessary equipment will not volatilize during use. The finned tube improves the real recognition ability of the equipment, and also better reflects its practical advantages under environmental protection.

Product Categories : Non Standard Custom Finned Tube

Home > Products > Non Standard Custom Finned Tube > Customized Cold Rolled Finned Tube Wound And Extruded

Send Inquiry

Mr. Mike

Tel:+86-0510-85189125

Fax:

Mobile Phone:+8618851577799

Email:mike@cnmcway.com

Address:406, Henghua Science park, No.20, No.58, Xiuxi Road, Binhu District, Wuxi, Jiangsu

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.