Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Status: New

Warranty Period: 3 Months

Applicable Industry: Food &Amp; Beverage Factory, Machinery Repair Shops, Manufacturing Plant, Hotels, Other

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Hot Product 2019

Place Of Origin: China

Types Of Parts: Finned Tube

Packaging: Wooden Box Packing

Transportation: Express,Air,Land,Ocean,Others

Supply Ability: 50000meter/month

Port: Shang Hai,Ning Bo

Payment Type: Paypal,T/T

Incoterm: FOB,CFR,CIF,EXW,FCA,CIP

Product Description

Laser Welding Finned Tube is a finned tube laser welding machine that integrates laser technology, hardware molds and numerical control automatic control. The operation is simple, and the manufacture is flexible and convenient. It overcomes a series of problems such as breakage, slow speed, poor molding, and wrinkling during the welding process of laser welding Finned Tubes . The company has successfully mastered laser welding of finned tubes and finned tubes such as heat exchangers. Production and coordination of all parameters and automatic clamping. Finned Tube Aluminum For Chemical Industry

The Finned Tube Heat Exchanger not only has the advantages of large heat transfer inherent in the heat sink, small temperature difference, small total weight, small size, and rapid thermal response, but also has the advantages of convenient assembly, easy maintenance, durability, Low Resistance loss, and The exhaust flow channel is conducive to separation and has the advantages of impervious to each other. Specifically, the finned tube Heat Exchanger has the following characteristics. Good overall heat transfer performance. The Finned Tube heat exchanger relies on the phase change of the internal working medium to achieve heat transfer. The fins on the outside of the heat pipe greatly increase the heat transfer area and greatly reduce the convective heat transfer heat resistance on both sides. Finned Tube Aluminum For Chemical Industry

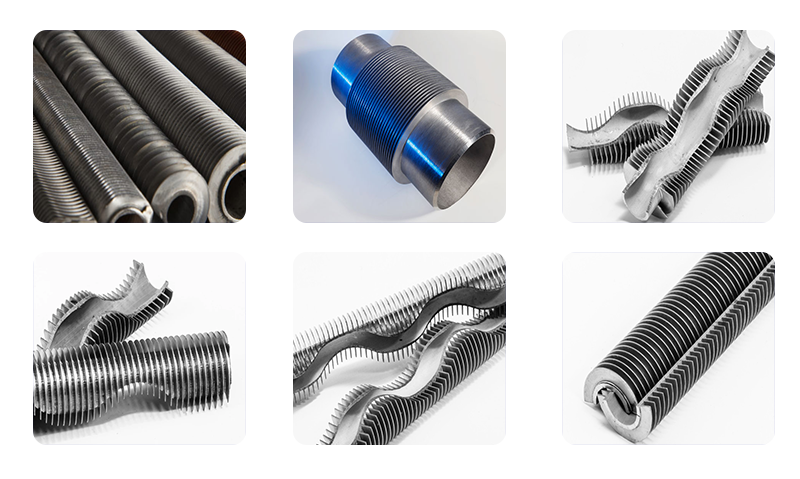

In order to improve the heat exchange efficiency, Fins are usually added to the surface of the heat exchange tube to increase the outer surface area (or inner surface area) of the heat exchange tube, so as to achieve the purpose of improving the heat exchange efficiency. Such heat exchange tubes are called finned tubes. . What are the classifications of finned tubes? Let's find out together.

Finned Tubes are divided into square Finned Tubes, spiral Finned Tubes, Longitudinally Finned Tubes, spiral serrated finned tubes, and Inner Finned Tubes according to shape and structure;

Finned Tubes are divided into: single metal finned tubes, bimetallic composite finned tubes according to the material;

Finned Tube Aluminum For Chemical IndustryFinned Tubes are classified according to different processing techniques: rolled finned tubes, welded finned tubes, rolled formed Finned Tubes, and suit formed Finned Tubes.

Laser Welded Finned Tubes have a certain ability to prevent dust accumulation. In the concept of treating more, the use of Finned Tubes is a fusion of emotions, which effectively carries many different skills in use. An efficient way to use it.

The application of Finned Tubes is very extensive now. Its main purpose is to perform heat exchange, so it is mainly installed on the surface of the heat exchange tube to improve heat exchange efficiency. For finned tubes, there are certain requirements for their performance, mainly including wear resistance, stability, large heat dissipation area, etc., especially when used in harsh environments, good performance is required. In addition to low thermal contact resistance and good dust-proof ability.

Features and advantages of Laser Welded Finned Tubes

1. Advanced process

Imported automatic Laser Welding achine imported from Germany, 100% welding between fins and tubes, no need to use filler materials, no impurities on the weld seam. Fins and tubes can be welded with different material combinations. Finned tubes can be simply bent and coiled. Due to the small heat-affected areas and weld seams, the material does not deform, while the tubes and fins undergo only slight microstructural changes.

2. High performance and lightweight

The thinnest base tube wall thickness that can be used in the Laser Welding Finned Tube process is 1.0mm, and the thinnest finned tube is 0.4mm. The unique winding process can ensure that the fin spacing is at least 2.0mm, and the fins are evenly distributed, and the bottom is flat and wrinkle-free, preventing dust accumulation, High Penetration Rate, and small thermal resistance, which greatly improves the heat transfer efficiency. High-frequency welded finned tubes can save energy by more than 30%.

Product Image

Application

Laser Welded Finned Tube is a new type,Finned Tube Aluminum For Chemical Industrywear-resistant and efficient heat exchange material in the finned tube welding industry. It is a high-efficiency and energy-saving heat exchange element with high heat exchange efficiency, large heat dissipation area, long service life, large temperature adaptability, wide range, high pressure, and meets the national energy-saving and environmental protection emission standards. Widely used in waste heat recovery, petrochemical, power plant boilers, economizers, passenger cars, industrial and civil building heating, refrigeration systems and other industries.

Production certification and certificate

Company Profile

Wuxi Mcway Equipment Technology Co., Ltd. is a high-tech enterprise integrating R & D, production and sales. The company develops and produces laser welded Finned Tubes and laser Welded Finned Tube Heat Exchanger. The base pipe materials are carbon steel, Stainless steel , alloy steel, copper tube, titanium tube and nickel tube; The fin strip is made of carbon steel, stainless steel, alloy steel, copper and titanium; Our company also has the ability to produce high-frequency welded Finned Tubes, Extruded Finned Tubes, embedded G-type finned tubes, wound L / LL/ KL type finned tubes and Low Finned Tubes , and can be customized into cylindrical and disk shapes according to customer requirements.

The company has strong technical force, complete production equipment, advanced production technology, perfect detection means, reliable and Stable quality, and has passed the IS09001 international quality system certification. Guided by customer demand, the company can customize heat conversion products and heat energy schemes according to customer demand; The company continues to improve the quality of products, and is committed to serving petroleum, chemical industry, pharmacy, food, power plant, metallurgy, textile printing and dyeing, new energy, shipbuilding, military industry, boiler, HVAC refrigeration, waste heat recovery and other fields, so as to provide high-quality thermal energy solutions and services for the global thermal energy industry.

Laser Welded Spiral Finned Tube is a new type, wear-resistant and efficient heat exchange material in the finned tube welding industry. The temperature range is wide, the pressure is high, and it meets the national energy-saving and environmental protection emission standards. It has the characteristics of high heat exchange efficiency, large heat dissipation area, long service life, wide temperature range, high pressure resistance, and compliance with national energy conservation and environmental protection emission standards. Wuxi Microway Equipment Technology Co., Ltd. has been focusing on the development and research of integral laser-welded finned tubes and single-layer double-layer spiral coils. Now it has been used in various fields such as boilers, chemicals, wall-hung boilers, ships, waste heat power generation, and home decoration. be applied within. The surface is the most used as the heating surface in the boiler industry. It is environmentally friendly, energy-saving and efficient. Laser-welded finned tubes are currently the most advanced products with irreplaceable advantages. The advantages in boiler, chemical industry and other heat exchange waste heat have been fully utilized.

Product Categories : Non Standard Custom Finned Tube

Home > Products > Non Standard Custom Finned Tube > Finned Tube Aluminum Fin Industrial Use

Send Inquiry

Mr. Mike

Tel:+86-0510-85189125

Fax:

Mobile Phone:+8618851577799

Email:mike@cnmcway.com

Address:406, Henghua Science park, No.20, No.58, Xiuxi Road, Binhu District, Wuxi, Jiangsu

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.