Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Brand: mcway

Status: New

Warranty Period: 6 Months

Applicable Industry: Hotels, Food &Amp; Beverage Factory, Machinery Repair Shops, Manufacturing Plant, Energy &Amp; Mining, Construction Works, Other

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Hot Product 2019

Place Of Origin: China

Types Of Parts: Finned Tube

Packaging: Wooden box packaging

Transportation: Ocean,Land,Express,Air,Others

Place of Origin: China

Supply Ability: 50000meter/month

Port: Shang Hai,Ning Bo

Payment Type: T/T,Paypal

Incoterm: CFR,FOB,CIF,EXW,FCA,CIP

The flue gas waste Heat Exchanger is a heat exchanger that can re absorb and utilize the heat energy in the high temperature flue gas. Now it is being used in many industries, and the use effect is also very obvious.

1. Introduction of flue gas waste heat exchanger

The flue gas waste heat exchanger is a device that uses itself to extract and reuse the heat energy carried in the flue gas, meeting the national strategic policy of promoting energy conservation and emission reduction. Compared with the basic boiler heat exchanger, the heat energy is not fully recovered and utilized, which leads to a large amount of waste gas being discharged after supply. This is not only a high cost investment, but also a high environmental pollution. The appearance of flue gas waste heat exchanger makes the waste heat recovery process more effective. As long as the heat energy is below the acid dew point, all the waste heat can be recovered to improve the system process efficiency.

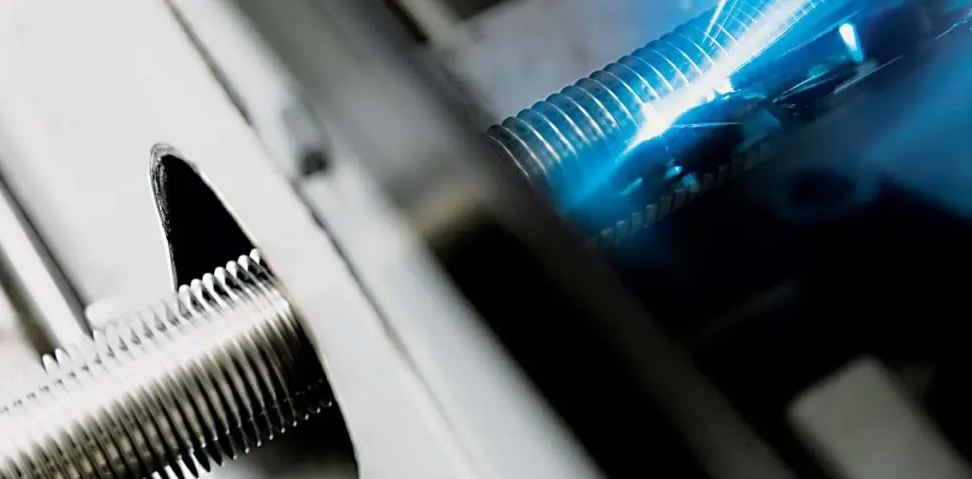

The Spiral Finned Tube is very simple and economical in the process of installation. Its equipment length can reach 6 meters, reducing the connection points, making the installation more economical and fast, and reducing the probability of water leakage at the connection. The maintenance is simple. After the installation of high-frequency welding spiral Finned Tube , the maintenance is basically unnecessary.

The spiral finned tube has High Efficiency. Its heat dissipation area is more than 8 times that of the smooth tube when it is used. During the operation, its interior will be more smooth, its internal water flow resistance is small, and its service life is long when it is operated. The mechanical strength of the finned tube is high, and the tensile strength is more than 200Mpa. The inside and outside of the tube are all hot-dip galvanized. Material of weldable fins: carbon steel, corrosion-resistant steel, Stainless steel, alloy steel. Form of weldable fins: solid teeth, open teeth.

Spiral Finned Tubes can be manufactured by various methods in the process of manufacturing. At present, finned tubes used in heat exchange equipment such as boilers and pressure vessels mainly have the following manufacturing methods:

High frequency resistance welding spiral finned tube

High frequency resistance welding of spiral Finned Tube is to introduce high power high-frequency current into the weldment, use the resistance heat generated by the current passing through the contact surface of the weldment joint and the adjacent area to make the welding contact surface reach the molten or semi molten plastic state, and then apply appropriate pressure to the welding contact surface to complete the welding of finned tube.

Fin Tube

Brazed spiral Finned Tube

Brazing spiral Finned tubes is to fill a filler metal with a melting point lower than that of the weldment between the weldments, and then heat the brazing temperature. When the weldment is not melted, the filler metal will be wetted and brazed, and the brazed joint will be formed depending on the expansion of the contact part of the weldment, thus completing the welding of spiral finned tubes.

The spiral finned tube is mainly an integral spiral finned tube that can be formed at one time after the tube is squeezed and rolled by using thick wall tubes under the condition of medium frequency continuous heating. See the current method for manufacturing finned tubes. The integral spiral Finned Tube developed by a domestic company and the self-made integral finned tube manufacturing equipment have been applied.

Finned Tubes, also known as heat sinks, are divided into single-metal finned tubes and bimetallic finned tubes.

Single metal finned tubes are rolled from aluminum tubes as a whole, called aluminum rolled finned tubes, have no contact thermal resistance, high strength, heat resistance and mechanical vibration, good thermal expansion performance, and have a considerable extended heat transfer surface. The heat exchanger made of this kind of finned tube is more effective than the serial fin or winding fin heat exchanger, and it is a heat exchanger with a wide range of uses. Single metal finned tubes can also be made by direct rolling of steel tubes or copper tubes.

Bimetal composite finned tubes are divided into steel-aluminum composite finned tubes and copper-aluminum composite finned tubes. Steel-aluminum composite finned tubes are made of (steel tubes, aluminum tubes; or stainless steel tubes, aluminum tubes) and then rolled out of fins, copper-aluminum composite finned tubes are made of (copper tubes, aluminum tubes) and then rolled The fins produced have the advantages of tight combination, small thermal resistance, good heat transfer performance, high strength, small flow loss, strong anti-corrosion performance, not easy to deform under long-term cold and hot conditions, and long working life.

The overall rolled fin has no burr, no wrinkle, Easy To Clean, easy to remove condensed water on the outer surface of the fin during wet cooling in heating and air conditioning engineering, and not easy to dust and scale in drying heating and other heat exchange occasions.

The common problem of spiral plate heat exchanger in the market is the blockage problem, which is difficult to be solved by both the manufacturer and the user. There are many impurities in the materials used by some manufacturers, and the pipe wall space of the equipment is relatively small, which is easy to be blocked during the import and export. Once the equipment is blocked, it needs to be stopped for maintenance and cleaning, which will affect the normal production process.

In the actual production process, we found that in addition to impurities or coking, the main problem of blockage is solidification, which is a physical phenomenon. In the production process, it is not convenient for us to add other chemical cleaning agents. To solve the problem of blockage of spiral plate heat exchanger in the production process, we must improve the production process, and only find ways to work hard in the cleaning process.

Q: Why buy from us instead of from other suppliers?

A: professional experience in process manufacturing, timely delivery and long-term after-sales service. High quality products fully meet any specific requirements. We provide one-stop solution services and competitive prices.

Q: Are your products customized?

A: Yes, we can customize new products according to your requirements or drawings.

Q: what are your terms of payment?

A: T / T, PayPal

Q: how to ensure quality?

A: before mass production, the final inspection is always carried out before shipment;

Since the establishment of the company, it is our constant pursuit and commitment to meet our customers with science and technology and humanized services based on advanced science and technology as the starting point and the needs of customers.

Finned Tube Heat Exchanger adopts the method of adding finned tube heat exchanger, which greatly improves the heat emission of radiator fins and further improves the role of heat emission of radiator fins. The finned tube heat exchanger is welded with low-carbon environment-friendly steel pipes, which is durable and emits heat for a long time. Our inspection and maintenance during use are still helpful to the service life of radiator fins.

There are many kinds of Laser Welded Finned Tubes in use. In operation, high-frequency welded finned tubes are mainly used. Although it is more advanced in product quality and production automation compared with inlay and brazing methods, it is difficult to weld the root of high-frequency welded finned tubes and there are wrinkles at the root, resulting in many shortcomings in heat exchange efficiency and convenient ash deposition prevention. In view of the above reasons and in response to the guidelines and policies on energy conservation and emission reduction. Technology of laser welding finned tube 1. The thickness of the base tube of the laser welded fin tube can be 0.8-1.5 mm, and the thickness of the fin can be 0.3-1 mm, which greatly saves the material cost compared with other processes. 2. High Penetration Rate can prevent gap corrosion, prolong service life and reduce heat transfer resistance. 3. Break through the material limit and use different materials for processing. 4. It is easy for secondary processing and can be directly used for coil and elbow. 5. The welding heat affected zone is small and the metallographic change is small, which makes the processing of small diameter finned tube possible. The materials of heat exchange Tubes and condensing tubes shall have heat transfer performance, good corrosion resistance, erosion resistance and abrasion resistance, and good strength, rigidity and plasticity, which are easy to process and manufacture. Laser welded finned tubes can effectively detect the smooth transition of the tube connection to a certain extent. The nozzle shall be more than 100mm higher than the pile top, and the nozzle height of each detection tube shall be consistent. The lower end of the tube shall be closed and the upper end shall be covered. There shall be no foreign matters in the tube and the tube body shall not be damaged.

Product Categories : Non Standard Custom Finned Tube

Home > Products > Non Standard Custom Finned Tube > Laser Welded Finned Tube Spiral Customized Finned Tube

Send Inquiry

Mr. Mike

Tel:+86-0510-85189125

Fax:

Mobile Phone:+8618851577799

Email:mike@cnmcway.com

Address:406, Henghua Science park, No.20, No.58, Xiuxi Road, Binhu District, Wuxi, Jiangsu

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.