Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Brand: MCWAY

Status: New

Warranty Period: 6 Months

Applicable Industry: Hotels, Manufacturing Plant, Machinery Repair Shops, Food &Amp; Beverage Factory, Construction Works, Energy &Amp; Mining, Other

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Hot Product 2019

Place Of Origin: China

Types Of Parts: Finned Tube

Packaging: Wooden box packaging

Transportation: Ocean,Land,Air,Express,Others

Place of Origin: CHINA

Supply Ability: 50000meter/month

Port: ShangHai,NingBo

Payment Type: T/T,Paypal

Incoterm: FOB,CFR,CIF,EXW,FCA,CIP

Feedback on quality, service, market feedback and suggestions. We can do better.

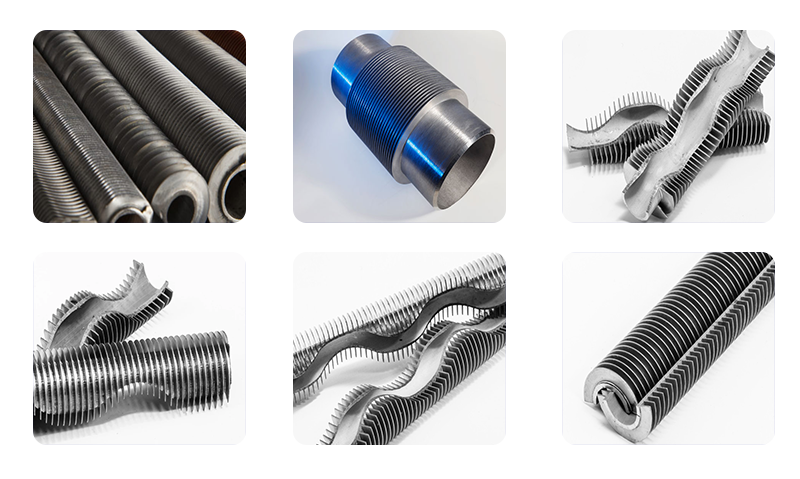

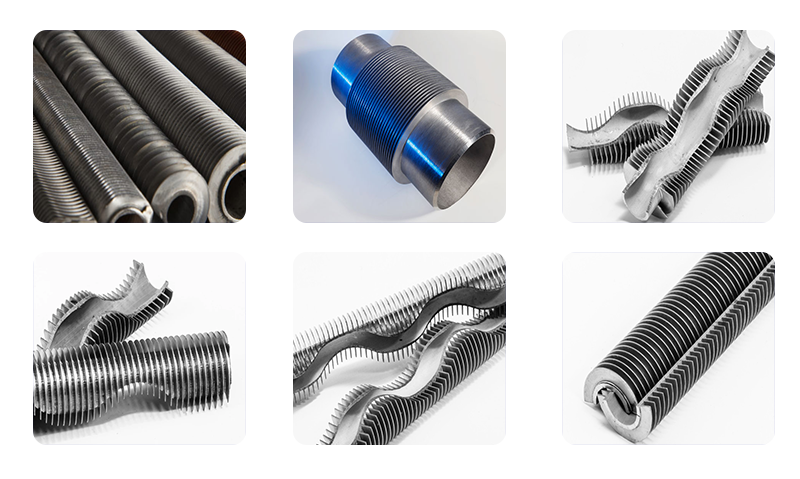

The Finned Heating Tube is made of high-quality Stainless steel , modified magnesium oxide powder, high-resistance electric heating alloy wire, stainless steel heat sink and other materials, and is made through advanced production equipment and technology, and has undergone strict quality management. The finned heating tube can It is installed in the blowing duct or other heating places with static and flowing air.Custom Laser Fin Tube .Custom Laser Finned Tubes .

The Finned heating Tube is a metal heat sink wound on the surface of ordinary components. Compared with ordinary elements, the heat dissipation area is expanded by 2.5 to 4 times, that is, the surface power load allowed by the finned elements is 1.5 to 2 times that of ordinary elements. Due to the shortened length of the element, the heat loss of itself is reduced. Under the same power condition, it has the advantages of fast temperature rise, uniform heating, good heat dissipation performance, high thermal efficiency, long service life, small heating device, and low cost. Reasonable design is carried out according to user requirements, which is convenient for installation.

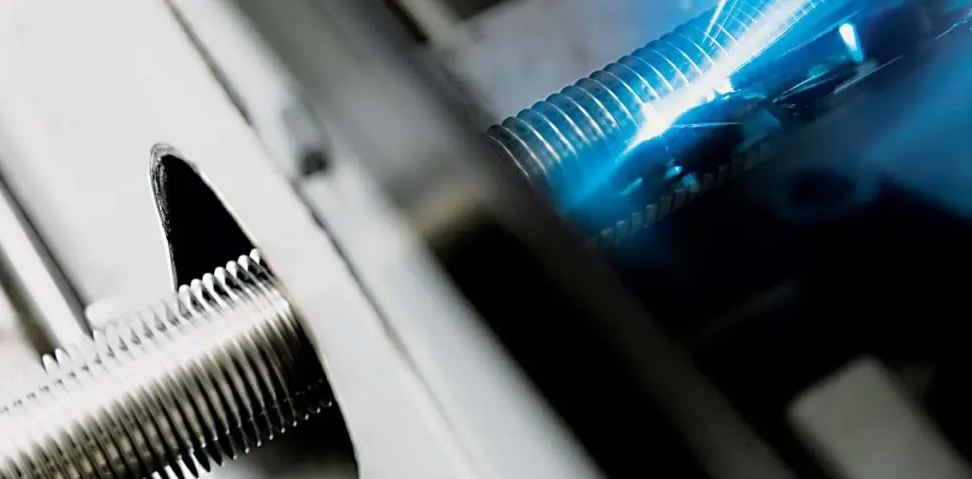

If the thermal conductivity of the two sides of the Laser Welded Finned Tube is relatively different, the fins should be installed on the side with the smaller thermal conductivity to achieve a Stable balance. Therefore, it is necessary to place the side with a small thermal conductivity outside the tube as far as possible during production to facilitate later installation operations. If the thermal conductivity on both sides is not high, only side panels can be assembled on both sides to enhance heat conduction. However, if the structure is limited, fins may not be added, as long as the two sides are balanced. In another case, if the thermal conductivity on both sides of the tube is large, it is not necessary to use finned tubes. Of course, in order to further improve the heat conduction, threaded pipes or corrugated pipes can be used instead of light pipes, and the effect is also very prominent.

They find application in the following industries and we produce finned tubes to meet the needs of the following industries

petrochemical refinery

chemical processing plant

Textile processing

power plant

Agricultural Drying Equipment

refrigeration industry etc.

Where are Finned Tubes used?

Finned Tube heat exchangers typically use air to cool or heat fluids such as air, water, oil or gas, or they can be used to capture or recover waste heat. These heat exchangers can be used in a wide range of industries including oil and gas, power generation, marine and boilers, nuclear power, marine, military and more

Finned Tubes (finned tube) are mainly Heat Exchanger Tubes used for transferring process heat.

Finned Tubes are essentially tubes with increased surface area. The amount of heat transferred from a particular surface is directly related to the surface area available to transfer heat. Therefore, increasing the heat transfer area as a whole can improve the heat transfer efficiency.

In finned tubes, the surface area of the tubes is increased by providing fins on the heat exchanger. These fins can be of various types, made of various materials, and designed in various ways according to the final requirements.

We have production facilities to produce various types of finned tubes as described below,Custom Laser Fin Tube

Extruded Finned Tubes (bimetallic finned tubes)

Low Finned Tubes (Integral Finned Tubes)

"G" type finned tube (Embedded Finned Tube)

"L"/"LL"/"KL" type finned tubes ( Wound Finned Tubes )

High Frequency Welded Finned Tubes.

Q: is your product customized?

A: Yes, we can customize new products according to your requirements or drawings.

Q: what are your terms of payment?

Answer: T / T, PayPal

Q: Why buy from us instead of from other suppliers?

A: professional experience in process manufacturing, timely delivery and long-term after-sales service. High quality products fully meet any specific requirements. We provide one-stop solution services and competitive prices.

Q: how to ensure quality?

A: before mass production, the final inspection is always carried out before shipment;

About us

The company has strong technical force, complete production equipment, advanced production technology, perfect testing means, reliable and stable quality, and has passed the IS09001 international quality system certification. The company is customer-oriented, and can customize heat conversion products and thermal energy solutions according to customer needs; the company continues to improve product quality, and is committed to serving petroleum, chemical, pharmaceutical, food, power plants, metallurgy, textile printing and dyeing, new energy, shipbuilding, military industry , boilers, HVAC, waste heat recovery and other fields, providing high-quality thermal solutions and services for the global thermal energy industry.

Finned Tubes are widely used in industries such as power and chemical industry, and many spiral heat exchange surfaces or threaded tubes can be regarded as finned tubes. It has a significant effect on expanding the heat transfer area and promoting turbulent flow, whether it is a single convective heat transfer or a phase change convective heat transfer. The structure of the Finned Tube Heat Exchanger is basically the same as that of the general shell and tube heat exchanger. Just use the finned tube instead of the light tube as the heat transfer surface. Finned tube heat exchangers are also often used to heat or cool the gas outside the tube, and steam or water is passed through the tube, such as air coolers, boiler economizers, radiators, etc.Laser Welded Fin Tube Discount.

The heat exchanger is the key equipment of the thermal system. The Fin Tube heat exchanger is a heat exchanger structure with high technical content and complicated production process. The cold and hot fluids are cross-flowed and exchanged between the walls. The main body of the tube is phase change heat transfer. The tubes are generally arranged in a serpentine shape with multiple tubes. The fins are divided into single, double or multi-row structures. This kind of heat exchanger is widely used in petrochemical, aviation, vehicles, power machinery, air separation, cryogenic, atomic energy, aerospace and other industrial fields. For example, superheaters, economizers, air preheaters, condensers, deaerators, feed water heaters, cooling towers, etc. in boiler thermal systems; hot blast stoves, air or gas preheaters, Waste heat boilers, etc.; evaporators, condensers, regenerators, etc. in refrigeration and low temperature systems; heating and cooling equipment widely used in the petrochemical industry, sugar liquid evaporators and pulp evaporators in the sugar and paper industries, These are numerous examples of applications for heat exchangers.

The advantages of finned tubes are mainly

1. Strong heat transfer capacity: Compared with light tubes, the heat transfer area can be increased by 2-30 times, and the heat transfer coefficient can be increased by 1-2 times.

2. Compact structure: Due to the increased heat transfer area per unit volume, the heat transfer capacity is enhanced. Compared with the light tube under the same heat load, the finned tube heat exchanger has fewer tubes, and the diameter or height of the cylinder can be reduced, because the structure is compact and Easy to set up.

3. More effective and reasonable use of materials: not only because of the compact structure and reduced material consumption, but also it is possible to flexibly select materials for heat transfer and process requirements, such as inlaid or welded finned tubes made of different materials;

| Serial Number | Name | Range |

| 1. | Outer Diameter Of Base Pipe | 10.0-89.0m |

| 2. | Fin Outer Diameter | 20.0-123.0mm |

| 3. | Fin Pitch | 2-13 Fins/inch |

| 4. | Fin Height | 5.0-17mm |

| 5. | Fin Thickness | 0.5-1mm |

| 6. | Maximum Pipe Length | 12.0m |

4. When the medium is heated, compared with the bare tube, the wall temperature of the finned tube under the same heat load is reduced, which is beneficial to reduce the high temperature corrosion and overtemperature damage of the metal surface.

Regardless of whether the medium is heated or cooled, the heat transfer temperature difference is smaller than that of the bare tube, which is beneficial to reduce fouling on the outer surface of the tube. Another important reason for the reduction of fouling is that the finned tube will not form a uniform overall fouling layer along the circumference or in the axial direction like the smooth tube. Break at the root of the fin, prompting the ridge scale to fall off by itself.

5. For phase conversion heat, the heat transfer coefficient or critical heat flux can be used. The main disadvantages of finned tubes are high cost and large flow resistance. The finned tubes such as air coolers are complex in technology, and their cost reaches 50-60% of the equipment cost; the resistance is large, resulting in large power consumption. However, if the shape is proper, the power consumption can be reduced, which is more cost-effective than the benefit of heat transfer enhancement.

Product Categories : Laser Welded Finned Tubes

Home > Products > Laser Welded Finned Tubes > Specializing In Manufacturing Laser Finned Tubes

Send Inquiry

Mr. Mike

Tel:+86-0510-85189125

Fax:

Mobile Phone:+8618851577799

Email:mike@cnmcway.com

Address:406, Henghua Science park, No.20, No.58, Xiuxi Road, Binhu District, Wuxi, Jiangsu

Related Products List

Mobile Site

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.