Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Status: New

Warranty Period: 6 Months

Applicable Industry: Hotels, Manufacturing Plant, Machinery Repair Shops, Food &Amp; Beverage Factory, Construction Works, Energy &Amp; Mining, Other

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Hot Product 2019

Place Of Origin: China

Types Of Parts: Finned Tube

Packaging: Wooden box packaging

Transportation: Ocean,Land,Air,Express,Others

Supply Ability: 50000meter/month

Port: ShangHai,NingBo

Payment Type: T/T,Paypal

Incoterm: FOB,CFR,CIF,EXW,FCA,CIP

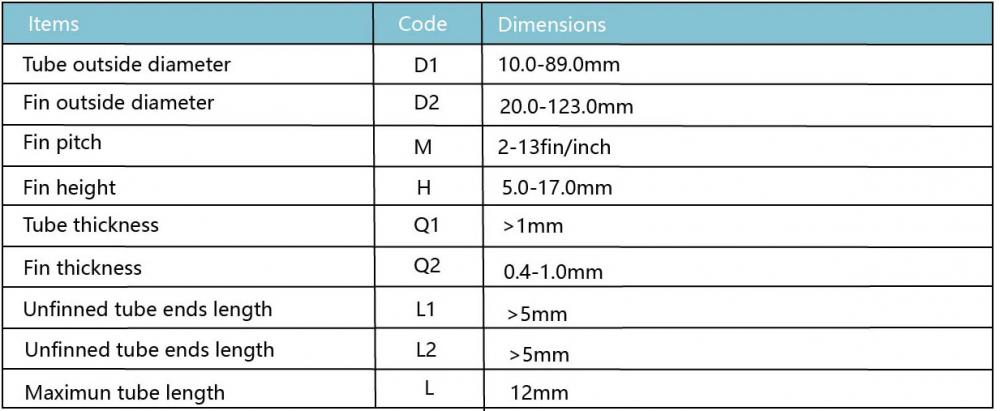

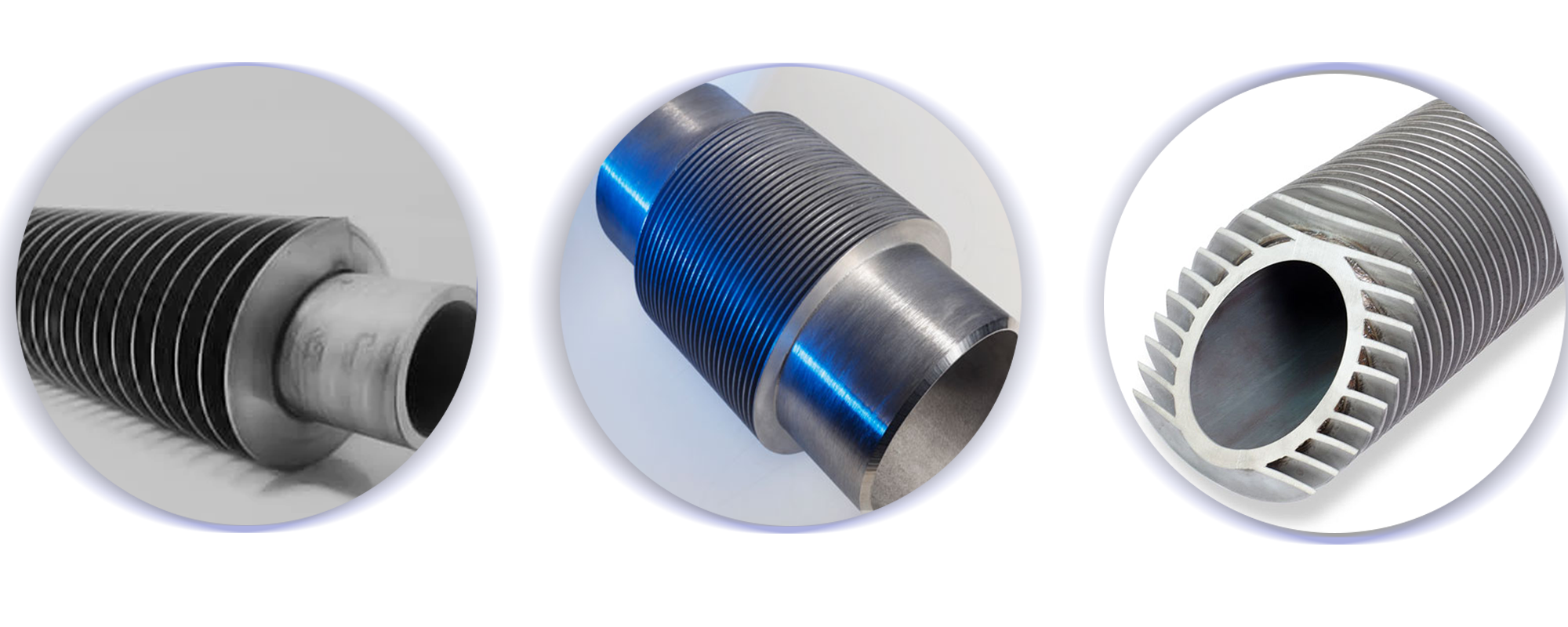

As the name implies, the Stainless Steel Finned Tube is a Finned Tube produced by using Stainless steel material through High Frequency welding process or aluminum extrusion process.

Stainless steel Finned Tubes have high thermal efficiency and heat dissipation area, long service life and suitable temperature range, and are widely used in petrochemical, economizer, waste heat recovery, greenhouse, power plant boiler greenhouse, industrial fields, such as wood drying, etc. .

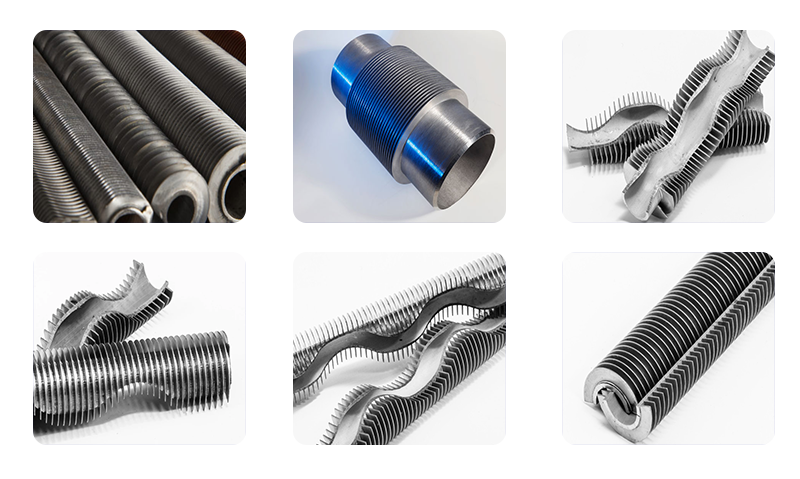

Our company selects High Quality Finned Tubes materials to reassure customers about products. Compared with other processes, laser welding of Finned Tubes can greatly save material costs, achieve High Penetration Rate, prevent gap corrosion, prolong service life, reduce heat transfer and thermal resistance, and dry laser welding of finned tubes is also more energy-saving and environment-friendly. Compared with high-frequency welding, it has the characteristics of large winging ratio, light weight and compact volume of assembled Heat Exchanger . Its materials include stainless steel, titanium, copper, carbon steel and other types. The selection of a variety of materials can maximize the application of products. At the same time, the thickness of the base Tube of the Fin Tube can be 0.8-1.5mm, and the thickness of the Fin Tube can be 0.3-1MM, which greatly saves the material cost compared with other processes.

Stainless steel Finned Tube Heat Eexchangers are mostly welded by steel pipes. Steel Finned Tube radiators have excellent heat dissipation performance, corrosion resistance and wear resistance, and the emergence of Finned Tube radiators has successfully replaced traditional heating radiators. There are many kinds of processing techniques for steel Finned Tube radiators, such as soldered fin type, wound Fin type, serial Fin type, etc., and users can choose according to their own needs.

Laser Welded Spiral Finned Tubes are used in civil wall-hung boilers, industrial boilers, etc. The use of German technology is just emerging in China, but it has a history of more than ten years in Europe. The advantage is that the contact thermal resistance is zero, and compared with high-frequency welding The heat exchanger has the characteristics of large chemical ratio, light weight, and compact volume of the assembled heat exchanger, which is more energy-saving and environmentally friendly, and meets the national emission requirements.

Stainless steel Laser Welded Spiral Finned Tubes:

The degree of automation is high, the automatic Fin Laser Welding machine can complete the welding at one time, and the synchronous winding can realize the welding depth of the fin foot and the pipe.

2. Laser welding, high firmness, high binding force. Laser Welding Finned Tubes is a metallurgical combination with a welding strength greater than 600MPa.

The Laser Welding machine has high precision and can weld finned tubes up to 8 meters long with an accuracy of 0.05mm.

Laser Welding can greatly improve the heat transfer coefficient.

The section length of laser welded fins is less than or equal to 2.5 mm, and the heat dissipation area is nearly 50% larger than that of high-frequency welded tubes (distance is greater than or equal to 4.5 mm), which greatly reduces the tube material and can also reduce the volume and variety of heat exchangers.

How will the Fin pitch affect the fin ratio?Laser Finned Tube For Drying

Often a smaller pitch is effective in increasing the fin ratio. When considering the nature of flowing gas and ash deposits, the following factors should be kept in mind.

severe heavy ash deposits

Such as the waste gas of electric furnace and converter in steel plant and industrial pit furnace, which has high ash content. If finned tubes are used for heat exchange, a larger fin spacing is recommended. For example, if the spacing is greater than 10mm, it is necessary to increase air discharge and choose a blower.

How to improve the production efficiency of Laser Welded Stainless Steel Finned Tubes and reduce production costs: At present, the production efficiency of Finned Tubes is still very low, and there is still a lot of room for improvement. As long as the development is good, the production cost will be greatly reduced. There are many factors that affect the production efficiency of finned tubes, mainly including the following factors:

Impedance matching problem: We all know that the electron tube is a voltage amplification component with a very high output impedance, and contact welding is a current heating welding process that requires a low-impedance power supply. Therefore, the impedance of the two does not match, and it is difficult to output more power. Only by changing the ratio of the pot circuit and adjusting the relative position of the contacts properly can a larger output be obtained.Laser Finned Tube For Drying

When the Finned Tube is in operation, it is a kind of heat exchange element. To a certain extent, it is to further improve the heat transfer efficiency. area, so that the effect of improving the heat transfer efficiency can be achieved, such a heat exchange tube. As a heat exchange element, Finned Tubes work for a long time under the condition of high-temperature industrial waste gas. For example, finned tubes used in boiler heat exchangers are used in harsh environments, high temperature and high pressure, and are in corrosive environments. This requires that the finned tubes should have a relatively high temperature. High performance parameters.

Finned Tubes have relatively high corrosion-resistant product performance during use; in fact, many times, when we are in the normal operation of an item, the application of Finned Tubes basically shows its unique environmental advantages , added a lot of additional functions, also improved the application functions on the basis of the original facilities, and better facilitated the use scenarios in daily life.Laser Finned Tube For Drying.

heavy dust deposits For example, the waste gas of electric furnace and converter in steel plant and industrial pit furnace has high ash content. If Finned Tubes are used for heat exchange, a larger fin spacing is recommended. For example, if the spacing is greater than 10mm, it is necessary to increase air discharge and choose a blower. Pay attention to occasions with little ash. Taking the exhaust of factory boilers and industrial boilers as an example, a fin spacing of 8mm is appropriate, but it should be designed to have self-blowing capability. No dust or light dust. For example, the exhaust port of natural gas combustion equipment or air cooler, the fin spacing can be 4-6mm. For the aluminum air cooler, also choose 3mm as the fin spacing. When the Finned Tube is in operation, it is a heat exchange element. To some extent, it is to further improve the heat transfer efficiency. Area, so that the effect of improving heat transfer efficiency can be achieved, such a heat exchange tube. As a heat exchange element, Finned Tubes work for a long time under the condition of high-temperature industrial waste gas. For example, the finned tubes used in boiler heat exchangers are used in harsh environments, high temperature and high pressure, and are in corrosive environments. This requires that the Finned Tubes should have relatively high High Performance parameters. Finned Tubes have relatively high corrosion-resistant product performance during use; in fact, many times, when we operate normally for an item, the application of Finned Tubes basically shows its unique environmental advantages. , added a lot of additional functions, also improved the application functions on the basis of the original facilities, and better facilitated the use scenarios in daily life. Wear resistance is also a relatively obvious characteristic of Finned Tubes. In the process of assembling some parts, the wear-resistant properties of Finned Tubes will always help the application of equipment durability. Some necessary devices are not used during use. Certain volatility, the real recognition ability of the Finned Tube lifting equipment also better reflects that it has more practical advantages under the protection of the environment. Q: Why buy from us instead of from other suppliers? A: Rofessional experience in process manufacturing, timely delivery and long-term after-sales service. High quality products fully meet any specific requirements. We provide one-stop solution services and competitive prices. Q: Are your products customized? A: Yes, we can customize new products according to your requirements or drawings. Q: What are your terms of payment? A: T / T, PayPal Q: How to ensure quality? A: Before mass production, the final inspection is always carried out before shipment; Since the establishment of the company, it is our constant pursuit and commitment to meet our customers with science and technology and humanized services based on advanced science and technology as the starting point and the needs of customers.

Wuxi Mcway Equipment Technology Co., Ltd. is a high-tech enterprise integrating R & D, production and sales. The company develops and produces Laser Welded Finned Tubes and laser welded Finned Tube Heat Exchanger. The base pipe materials are carbon steel, stainless steel, alloy steel, copper tube, titanium tube and nickel tube; The fin strip is made of carbon steel, stainless steel, alloy steel, copper and titanium; Our company also has the ability to produce high-frequency welded Finned Tubes, Extruded Finned Tubes, embedded G-type finned tubes, wound L / LL/ KL type finned tubes and Low Finned Tubes, and can be customized into cylindrical and disk shapes according to customer requirements.

The company has strong technical force, complete production equipment, advanced production technology, perfect detection means, reliable and Stable quality, and has passed the IS09001 international quality system certification. Guided by customer demand, the company can customize heat conversion products and heat energy schemes according to customer demand; The company continues to improve the quality of products, and is committed to serving petroleum, chemical industry, pharmacy, food, power plant, metallurgy, textile printing and dyeing, new energy, shipbuilding, military industry, boiler, HVAC refrigeration, waste heat recovery and other fields, so as to provide High Quality thermal energy solutions and services for the global thermal energy industry.

Product Categories : Laser Welded Finned Tubes

Home > Products > Laser Welded Finned Tubes > Laser Finned Tube With High Heat Transfer Coefficient

Send Inquiry

Mr. Mike

Tel:+86-0510-85189125

Fax:

Mobile Phone:+8618851577799

Email:mike@cnmcway.com

Address:406, Henghua Science park, No.20, No.58, Xiuxi Road, Binhu District, Wuxi, Jiangsu

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.