Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Brand: MCWAY

Status: New

Warranty Period: 6 Months

Applicable Industry: Hotels, Manufacturing Plant, Machinery Repair Shops, Food &Amp; Beverage Factory, Other

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Hot Product 2019

Place Of Origin: China

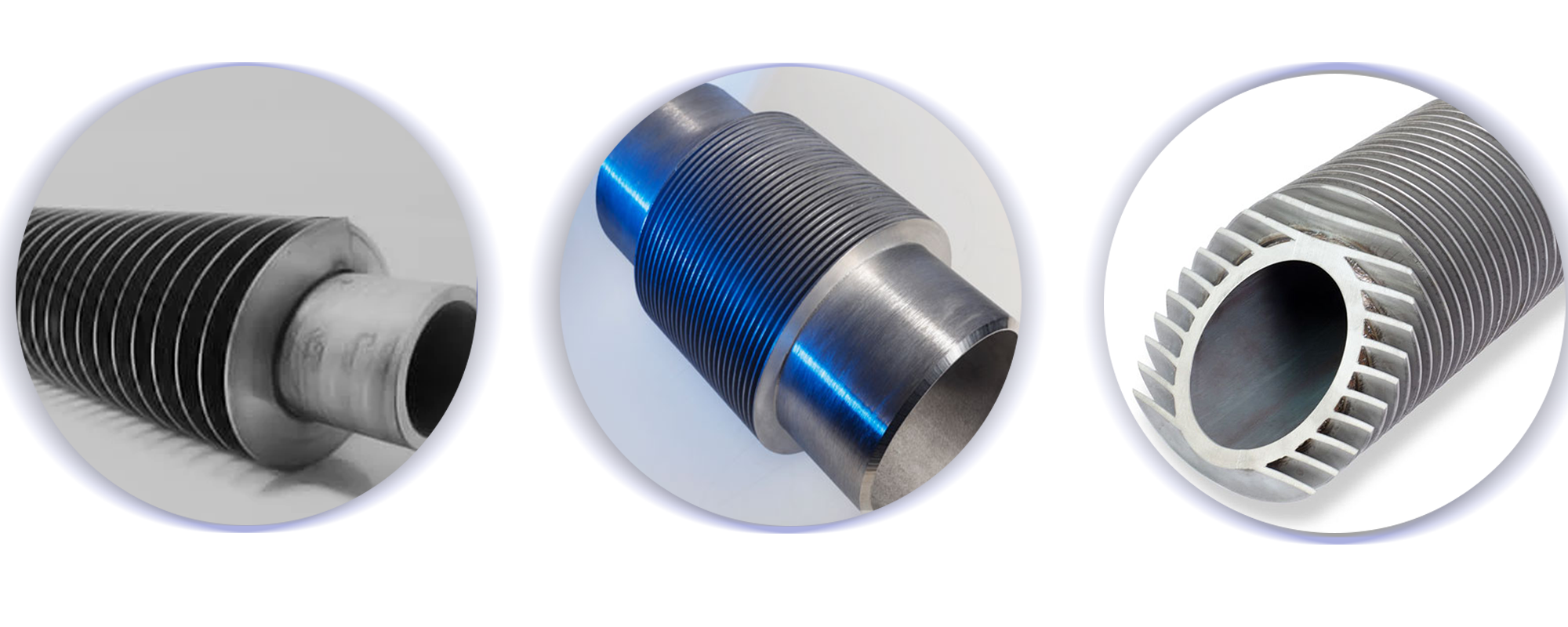

Types Of Parts: Finned Tube

Packaging: Wooden Box Packing

Transportation: Ocean,Land,Air,Express,Others

Place of Origin: CHINA

Supply Ability: 50000meter/month

Port: Shang Hai,Ning Bo

Payment Type: T/T,Paypal

Incoterm: EXW,CIF,CFR,FCA,CIP

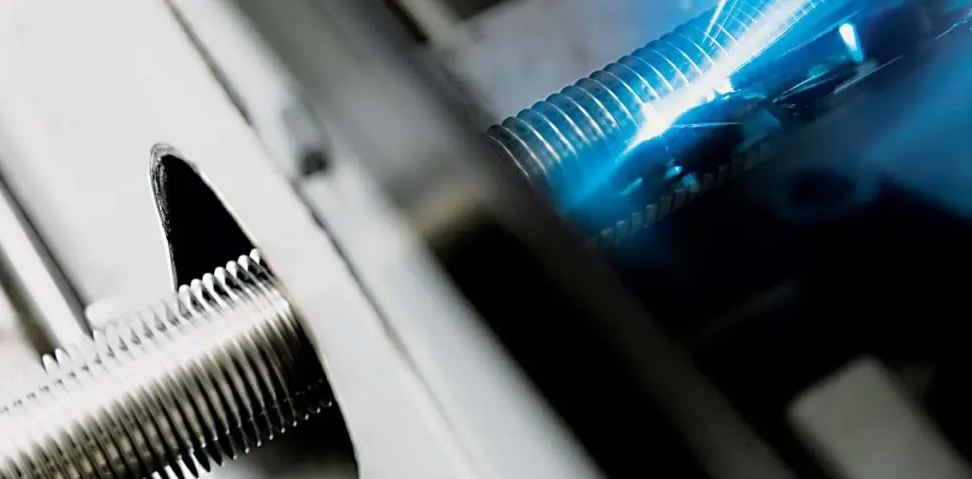

Advanced technology

The fully automatic laser welding machine imported from Germany ensures 100% penetration of fins and base tubes.

High performance, lightweight

Laser Welded Finned Tubes can use the thinnest base tube wall of 1.0mm and the thinnest fins of 0.4mm, which greatly reduces thermal resistance. The unique winding process fins are evenly distributed, and the bottom is flat and wrinkle-free, preventing dust accumulation and greatly improving heat transfer efficiency。

Application of Laser Welded Finned Tubes in Boilers and Wall-hung Furnaces

:.

Recommended Industrial Laser Welded Finned Tubes

The Finned Tube Heat Exchanger adopts the method of adding laser welded finned tubes, which greatly improves the heat exchange efficiency, Strong Corrosion Resistance, longer service life, wider temperature range, high pressure, and conforms to the national Energy-saving and environmental protection emission standards and other characteristics.

Recommended Industrial Laser Welded Finned Tubes.Finned Tube heat exchangers are indispensable machines and equipment in the overall heat transfer in industrial manufacturing. It is widely used in heat exchanger industries in petroleum refining, chemical industry, medicine, food, power plants, new energy, boilers, nuclear power and other fields. In recent years, in view of the development trend of new technology application and new energy development, improving the performance of heat exchangers has been paid more and more attention by the industrial field.

Wuxi Microway Equipment Technology Co., Ltd. warmly welcomes people and friends at home and abroad to come to negotiate and cooperate. We hope that our products will accompany your business to a brilliant tomorrow.

Advantages of Laser Welded Finned Tubes

A high-efficiency and energy-saving heat exchange element, new type, wear-resistant, and large heat dissipation area

➔ long life

Easy To Clean and sanitize

Laser finned tubes meet the requirements:

➔ Food and Beverage

➔ Pharmaceutical industry

➔Petroleum refining, chemicals, power plants, boilers, etc.

Optimum heat transfer, reduced material

➔ Smaller heat exchanger footprint

➔ Reduce investment costs

Match the challenges in your process

➔ Reduced downtime

➔ Lower operation and maintenance costs

➔ Reduce investment costs

The tube can be bent in the finned section

➔ Fast and easy to handle

The tube is virtually unaffected by the welding process

➔ Small tubule walls are possible

➔ Reduced footprint and weight of the heat exchanger

➔ Proven design

In order to improve heat Exchange Efficiency, Fins are usually added to the surface of heat exchange tubes to increase the outer surface area (or inner surface area) of heat exchange tubes, so as to achieve the purpose of improving heat exchange efficiency. Such heat exchange tubes are called fins. Sheet tube. What are the classifications of Finned Tubes? Let's find out together.

Finned tubes are divided into square finned tubes, spiral finned tubes, longitudinally finned tubes, spiral serrated finned tubes, and inner finned tubes according to shape and structure;

Finned Tubes are divided into: single metal finned tubes, bimetallic composite finned tubes;

Finned Tubes are divided into different processing techniques: rolling finned tubes, welded Finned Tubes, rolling formed finned tubes, and suit formed finned tubes.

We recommend laser-welded finned tubes for industrial use. Laser-welded composite finned tubes have a certain ability to prevent dust accumulation. In the concept of treating more, the use of finned tubes is a fusion of emotions, which is effective It carries a lot of different skills in use, and it is also an effective way to use it.

Laser welded finned tubes are a relatively Stable product

Laser Welded Finned Tube is a relatively mature and stable finned tube product with good advantages:

1. The thickness of the base tube of the laser-welded finned tube can be 0.5-1.mm, and the thickness of the fin can be 0.5-1.mm, saving material costs.

2. High permeability can prevent crevice corrosion, longer life and reduce heat transfer resistance.

3. Different materials can be used for processing.

4. Laser welded finned tubes are easy for secondary processing, and can directly crimp and bend pipes.

5. The heat-affected zone of welding is small, the metallographic change is small, and small-diameter finned tubes can be processed.

Frequently Asked Questions (FAQ) about Laser Welded Finned Tubes:

1. What is the use of Finned Tubes?

Finned tubes are the main components of heat exchangers. They are a series of tubes to which fins have been added on the outside to increase the contact area with the fluid outside to exchange heat as well as between the fluid inside the tube and the fluid outside the tube.

2. How are Finned Tubes made?

Fully automatic laser welding machine imported from Germany, 100% welding between fins and tubes, no need to use filler material, no impurities on the weld. Fins and tubes can be welded with different material combinations.

3. What are the characteristics of Laser Welded Finned Tubes?

· Finned Tubes can be easily bent and coiled

· Small heat affected zone

· The material will not deform

· Only slight microstructural changes in tubes and fins

· High heat utilization to form seams

Increased safety due to avoidance of crevice corrosion due to high weld integrity between tube and fins

· The weld seam is free of impurities, since laser welding is performed under a protective atmosphere

4. What is finned tube welding?

In the finned tube welding process, a rolled steel strip is continuously welded in a helical pattern on the outside diameter of the tube. The welds produced in this process are true forged, blacksmith welds. This type of weld consists of fusion between two parts of the parent metal without the introduction of filler material.

Selection and acceptance of laser welded Finned Tubes

The fan top finned tube is applied to the light heat sink, which is made of copper sensitive alloy. Its elastic function is to provide the resultant force for the matching of the heat sink and the module case. This structure is simple to manufacture and use, but has low fin efficiency. Therefore, fan top devices are applied to milliwatt transistors. Finned tubes can be designed according to different shapes, such as uniform rectangular straight ribs, triangular straight ribs, trapezoidal straight ribs and concave parabolic straight ribs.

No matter which type of laser-welded finned tube you choose, you should strictly check its surface quality and internal quality. In general, the requirements for its surface quality include that the lath is well processed, the surface quality is uniform, and the coating is not allowed to fall off or not cover; the cladding should be tightly bonded to the core alloy, and there should be no gaps or gaps between them. Cracks after multiple bends are not allowed.

Reasons to choose us:

We are one of the finned tube manufacturers in China, our products have been sold all over the world for many years and have been highly appraised by customers all over the world. We have a complete service team, complete production equipment and strict quality management system to fully guarantee your procurement needs and transaction security. We ensure that every product delivered is qualified. When you contact us to inquire about your order, we will have professional technical engineers to conduct detailed docking with you on technical issues to ensure that the products meet your needs. Our sales managers are on call 24 hours a day to ensure prompt and efficient service.

Product Categories : Laser Welded Finned Tubes

Home > Products > Laser Welded Finned Tubes > Recommended Industrial Finned Tube Laser Welding Finned Tube

Send Inquiry

Mr. Mike

Tel:+86-0510-85189125

Fax:

Mobile Phone:+8618851577799

Email:mike@cnmcway.com

Address:406, Henghua Science park, No.20, No.58, Xiuxi Road, Binhu District, Wuxi, Jiangsu

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.