Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Status: New

Warranty Period: 6 Months

Applicable Industry: Hotels, Manufacturing Plant, Machinery Repair Shops, Food &Amp; Beverage Factory, Construction Works, Energy &Amp; Mining, Other

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Hot Product 2019

Place Of Origin: China

Types Of Parts: Finned Tube

Packaging: Wooden Box Packing

Transportation: Express,Air,Land,Ocean,Other

Supply Ability: 50000meter/month

Port: Shang Hai,Ning Bo

Payment Type: T/T,Paypal

Incoterm: FOB,CFR,CIF,EXW,FCA,CIP

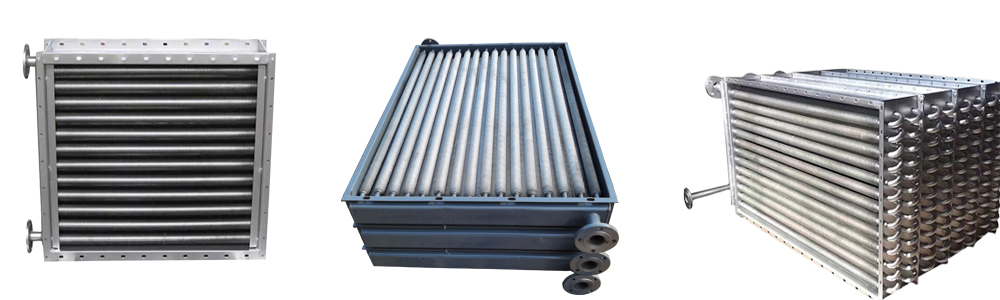

The Heat Exchanger is mainly composed of many single heat pipes in the process of manufacturing. The number of heat pipes mainly depends on the size of heat exchange. In order to improve the heat exchange coefficient of gas, the method of adding fins to the pipes is often adopted, which can greatly reduce the number of heat pipes required. Integral heat pipe heat exchanger is mainly divided into gas-gas type, gas-steam type and gas-liquid type.

Heat pipe type gas-gas heat exchanger is mainly composed of shell, heat pipe elements and cold and hot fluid inlet and outlet interfaces. The shell is a steel structure, one side is a hot fluid channel, the other side is a cold fluid channel, and the center is separated by a tube plate. Insulation layers are arranged between the upper and lower orifice plates of the shell and the cover plate and on both sides of the equipment. The upper and lower cover plates are of removable structure, which is convenient for maintenance and replacement of heat pipes.

The heat exchanger is mainly composed of two parts when it is manufactured, the heat pipe steam generator and the steam water separation equipment. The heat pipe evaporation generator is a new type of evaporation equipment, which uses the heat pipe with excellent heat conduction function as the heat transfer element. High frequency welded fins are selected in the heating section of the heat pipe to enhance heat transfer. Therefore, the whole set of equipment has high heat transfer efficiency, compact equipment structure, and small resistance of hot fluid movement. Moreover, the existence of the heat pipe makes the heating and vaporization of water end outside the flue, and the separation of steam and water ends in the steam drum. This is different from the general flue type waste heat boiler. At the same time, the water sleeve and the steam drum are connected by pipes. The length of the pipes can be adjusted at will, and the on-site installation is sensitive. The whole set of equipment has no rolling parts, and the operation is reliable and the operation and repair are convenient.

Industrial Finned Tubes are different from domestic ones in that they do not excessively pursue beautiful appearance, and more requirements are better performance and longer service life, and they are selected according to regions and places of use.

1: Security

No matter what the scene and purpose, when selecting finned tubes, it is necessary to select finned tubes with high safety performance, and first select finned tubes that can ensure the safety of people and property.

2: Durability

For plants with particularly serious ash deposition, such as iron and steel plants and industrial kilns, large fin pitch shall be selected for heat exchange of finned tubes to minimize the loss of finned tubes, so as to maximize the durability and service life of finned tubes.

The medium temperature of the heat exchanger depends on the process conditions, and the medium temperature cannot be too high or too low, so scaling may occur,

Precipitation, crystallization and other phenomena may worsen heat transfer, so we should have a reasonable utilization temperature. The temperature difference at the hot end shall not be less than 20

The temperature difference at the cold end shall not be less than 5 ° C. the initial temperature of the condensing agent in the cooler shall be higher than the freezing point of the cooled fluid. If

It is the solidification of the gas without solidifying property. The temperature of the condensing agent should be five degrees Celsius lower than that of the solidified gas, and the Wenchang of the air should not be less than

Determine the heat transfer required for finned tubes

The first step is to determine how much heat transfer is required and how many heat transfer surfaces are required. This will help determine which type of Fin Tube is the best heat dissipation solution, including the necessary fin surface requirements and the ideal material. What fin tube geometry is needed to achieve your vision?

You should also determine the necessary flow rate, which will affect the required diameter of the finned tubes. Which is affected by the pipe size.

how much pressure drop is required?

what hydraulic diameter is required?

what is the flow length on each fluid side of the heat exchanger?

what is the minimum free flow area?

what do you need in the forehead area?

what is the flow length on each fluid side of the heat exchanger?

Heat transfer can be improved by increasing the number of tubes or increasing the length of finned tubes.

Q: Why buy from us instead of from other suppliers?

A: professional experience in process manufacturing, timely delivery and long-term after-sales service. High quality products fully meet any specific requirements. We provide one-stop solution services and competitive prices.

Q: Are your products customized?

A: Yes, we can customize new products according to your requirements or drawings.

Q: what are your terms of payment?

A: T / T, PayPal

Q: how to ensure quality?

A: before mass production, the final inspection is always carried out before shipment;

Since the establishment of the company, it is our constant pursuit and commitment to meet our customers with science and technology and humanized services based on advanced science and technology as the starting point and the needs of customers.

Wuxi Mcway Equipment Technology Co., Ltd. is a high-tech enterprise integrating R & D, production and sales. The company develops and produces Laser Welded Finned Tubes and laser welded Finned Tube Heat Exchanger. The base pipe materials are carbon steel, Stainless steel, alloy steel, copper tube, titanium tube and nickel tube; The fin strip is made of carbon steel, stainless steel, alloy steel, copper and titanium; Our company also has the ability to produce high-frequency welded finned tubes, Extruded Finned Tubes, embedded G-type finned tubes, wound L / LL/ KL type finned tubes and Low Finned Tubes, and can be customized into cylindrical and disk shapes according to customer requirements.

The company has strong technical force, complete production equipment, advanced production technology, perfect detection means, reliable and Stable quality, and has passed the IS09001 international quality system certification. Guided by customer demand, the company can customize heat conversion products and heat energy schemes according to customer demand; The company continues to improve the quality of products, and is committed to serving petroleum, chemical industry, pharmacy, food, power plant, metallurgy, textile printing and dyeing, new energy, shipbuilding, military industry, boiler, HVAC refrigeration, waste heat recovery and other fields, so as to provide high-quality thermal energy solutions and services for the global thermal energy industry.

Product Categories : Finned Tubes Heat Exchanger

Home > Products > Finned Tubes Heat Exchanger > 304 Stainless Steel Finned Tube Heat Exchanger

Send Inquiry

Mr. Mike

Tel:+86-0510-85189125

Fax:

Mobile Phone:+8618851577799

Email:mike@cnmcway.com

Address:406, Henghua Science park, No.20, No.58, Xiuxi Road, Binhu District, Wuxi, Jiangsu

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.