Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Status: New

Warranty Period: 6 Months

Applicable Industry: Hotels, Manufacturing Plant, Machinery Repair Shops, Food &Amp; Beverage Factory, Construction Works, Energy &Amp; Mining, Other

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): None

Showroom Location (in Which Countries Are There Sample Rooms Overseas): None

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: Hot Product 2019

Place Of Origin: China

Types Of Parts: Finned Tube

Packaging: Wooden Box Packing

Transportation: Express,Air,Land,Ocean,Other

Supply Ability: 50000meter/month

Port: Shang Hai,Ning Bo

Payment Type: T/T,Paypal

Incoterm: FOB,CFR,CIF,EXW,FCA,CIP

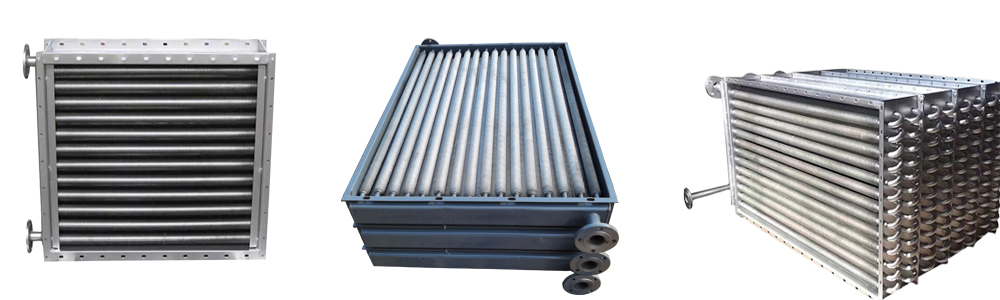

Air Heat Exchanger as Finned Tube heat exchanger

Gaseous medium and liquid

The heat transfer between finned tube heat exchangers is usually called air / water heat exchanger or gas / water heat exchanger. The heat transfer between gas (such as air) and liquid (such as water) occurs in the air / water heat exchanger. In order to improve the heat transfer from gas to liquid, fins made of well heat transfer material are placed on the pipe.

Generally, air / water heat exchangers are used as exhaust gas heat exchangers to obtain energy from warm or hot exhaust gases. Finned tube heat exchangers can also be used as air heaters, air coolers or condensers.

Finned tube heat exchangers have tubes with extended outer surface area or fins to enhance the heat transfer rate of the additional area of the fins. Finned Tubes or tubes with extended surface area can improve the heat transfer rate by increasing the effective heat transfer area between the tube and the surrounding fluid. The fluid around the finned tube may be processing fluid or air.

In order to design finned tube heat exchangers to increase the heat transfer area, the heat calculation of the required heat transfer area and the optimal spacing of tubes to create the required surface area are two parts of the problem. Increasing the heat transfer area means improving the efficiency of the heat exchanger.

Air heat exchanger as finned tube heat exchanger

Gaseous medium and liquid

The heat transfer between finned tube heat exchangers is usually called air / water heat exchanger or gas / water heat exchanger. The heat transfer between gas (such as air) and liquid (such as water) occurs in the air / water heat exchanger. In order to improve the heat transfer from gas to liquid, fins made of well heat transfer material are placed on the pipe.

Generally, air / water heat exchangers are used as exhaust gas heat exchangers to obtain energy from warm or hot exhaust gases. Finned tube heat exchangers can also be used as air heaters, air coolers or condensers.

Heat recovery with finned tube heat exchanger

Generally, air / water heat exchangers will be used for heat recovery. Warm exhaust gases (gases) that are often not used in the environment can be effectively used for heat recovery with the help of air / water heat exchangers. In this application, finned tube heat exchanger is also called economizer. In this case, other terms are preheater or heat exchanger.

Finned heat exchanger is the most widely used heat exchange equipment in gas and liquid heat exchangers. It can enhance heat transfer by adding fins to the common base tube. The base pipe can be steel pipe; Stainless steel pipe; Copper pipe, etc. Fins can also be made of steel strips; Stainless steel strip, copper strip, aluminum strip, etc.

The tube fin heat exchanger is commonly used in the air conditioning system. The working medium at the fin side is mostly air, and the tube is filled with water or refrigerant. The thermal resistance at the air side accounts for more than 70% of the total thermal resistance of the heat exchanger. Therefore, the heat exchange capacity of the air at the fin side is the standard to measure the efficiency of the heat exchanger.

In order to achieve the largest possible transfer surface inside the heat exchanger, fins

Put on the tubing system. The fins are pressed on the tube mechanically. Therefore, different materials can be combined. The materials for pressing fins (such as stainless steel, copper, aluminum) may vary in the height and thickness of fins and the distance between fins. Depending on the application, these parameters will be defined. The application of this type of heat exchanger can be found in process technology, food industry, air conditioning technology and many other industries.

Heat exchanger is the core equipment to realize heat transfer, and it has key applications in power system, metal smelting system, petroleum industry and other industries. Compared with plate and plate fin heat exchangers, finned tube heat exchangers are more widely used. At the same time, the tube fin heat exchanger has the advantages of easy production and assembly, low cost, etc.

Q: Why buy from us instead of from other suppliers?

A: professional experience in process manufacturing, timely delivery and long-term after-sales service. High quality products fully meet any specific requirements. We provide one-stop solution services and competitive prices.

Q: Are your products customized?

A: Yes, we can customize new products according to your requirements or drawings.

Q: what are your terms of payment?

A: T / T, PayPal

Q: how to ensure quality?

A: before mass production, the final inspection is always carried out before shipment;

Since the establishment of the company, it is our constant pursuit and commitment to meet our customers with science and technology and humanized services based on advanced science and technology as the starting point and the needs of customers.

Wuxi Mcway Equipment Technology Co., Ltd. is a high-tech enterprise integrating R & D, production and sales. The company develops and produces Laser Welded Finned Tubes and Laser Welded Finned Tube Heat Exchanger. The base pipe materials are carbon steel, stainless steel, alloy steel, copper tube, titanium tube and nickel tube; The fin strip is made of carbon steel, stainless steel, alloy steel, copper and titanium; Our company also has the ability to produce high-frequency welded finned tubes, Extruded Finned Tubes, embedded G-type finned tubes, wound L / LL/ KL type finned tubes and Low Finned Tubes, and can be customized into cylindrical and disk shapes according to customer requirements.

The company has strong technical force, complete production equipment, advanced production technology, perfect detection means, reliable and Stable quality, and has passed the IS09001 international quality system certification. Guided by customer demand, the company can customize heat conversion products and heat energy schemes according to customer demand; The company continues to improve the quality of products, and is committed to serving petroleum, chemical industry, pharmacy, food, power plant, metallurgy, textile printing and dyeing, new energy, shipbuilding, military industry, boiler, HVAC refrigeration, waste heat recovery and other fields, so as to provide high-quality thermal energy solutions and services for the global thermal energy industry.

Product Categories : Finned Tubes Heat Exchanger

Home > Products > Finned Tubes Heat Exchanger > Finned Tube Heat Exchanger In Drying Room

Send Inquiry

Mr. Mike

Tel:+86-0510-85189125

Fax:

Mobile Phone:+8618851577799

Email:mike@cnmcway.com

Address:406, Henghua Science park, No.20, No.58, Xiuxi Road, Binhu District, Wuxi, Jiangsu

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.